Bottle to Bottle recycling and PET fiber recycling are well known applications proving the excellent recyclability of PET. But what about PET sheet recycling?

A big challenge in PET sheet recycling is the material composition, as a PET sheet often consists of a PET/PE or G-PET structure. Conventional Polycondensation Equipment CANNOT upcycle this product.

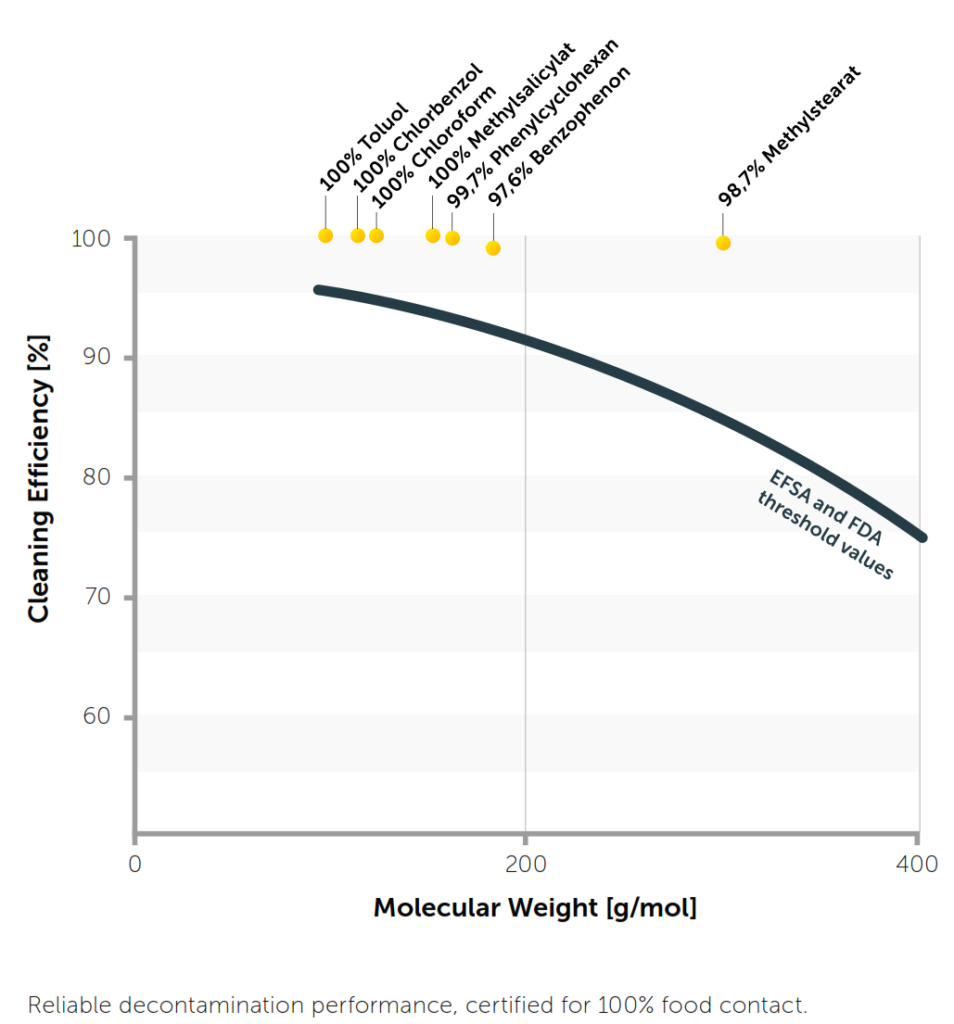

Next Generation Recycling (NGR) developed a revolutionary system called the P:REACT and the Liquid State Polycondensation (LSP), which uses PET’s inherent tendency to condense under vacuum in the melt phase. This condensation results in an extremely quick increase in the iV value. The vacuum decontaminates the material by removing harmful chemicals. This ensures that the material can be used downstream for 100% food-safe applications approved by the FDA and EFSA.

What kind of PET materials can the NGR P:REACT recycle?

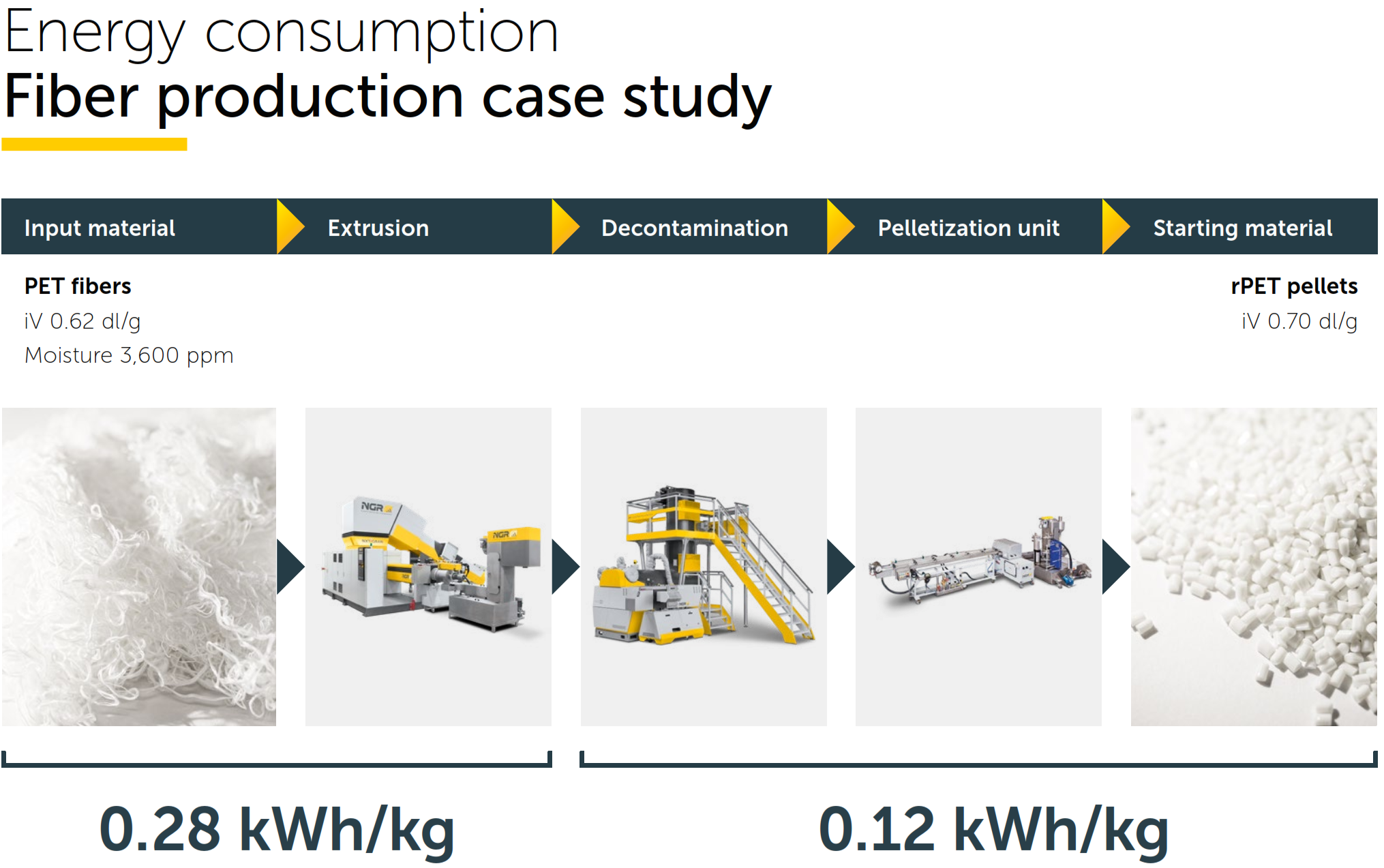

An extremely wide range of PET materials and material shapes are fed into the system. Materials including bottle flakes, punch scrap or even PET fibers are all equally suitable.

- PET fibers, fiber spinning

- PET nonwoven, post industrial scrap

- Purges

- PET film, automotive airbag

- PET bottle flakes, post washing line

- PET bottles mixed color flakes, post washing line

- PET preforms, injection molding and blow molding

- PET wovens, post industrial scrap

- PET trays, thermoforming

- PET skeleton, thermoforming

NGR’s LSP method offsets fluctuations in mixture ratios of the fed materials, opening the door for flexible cost structuring depending on material availability.

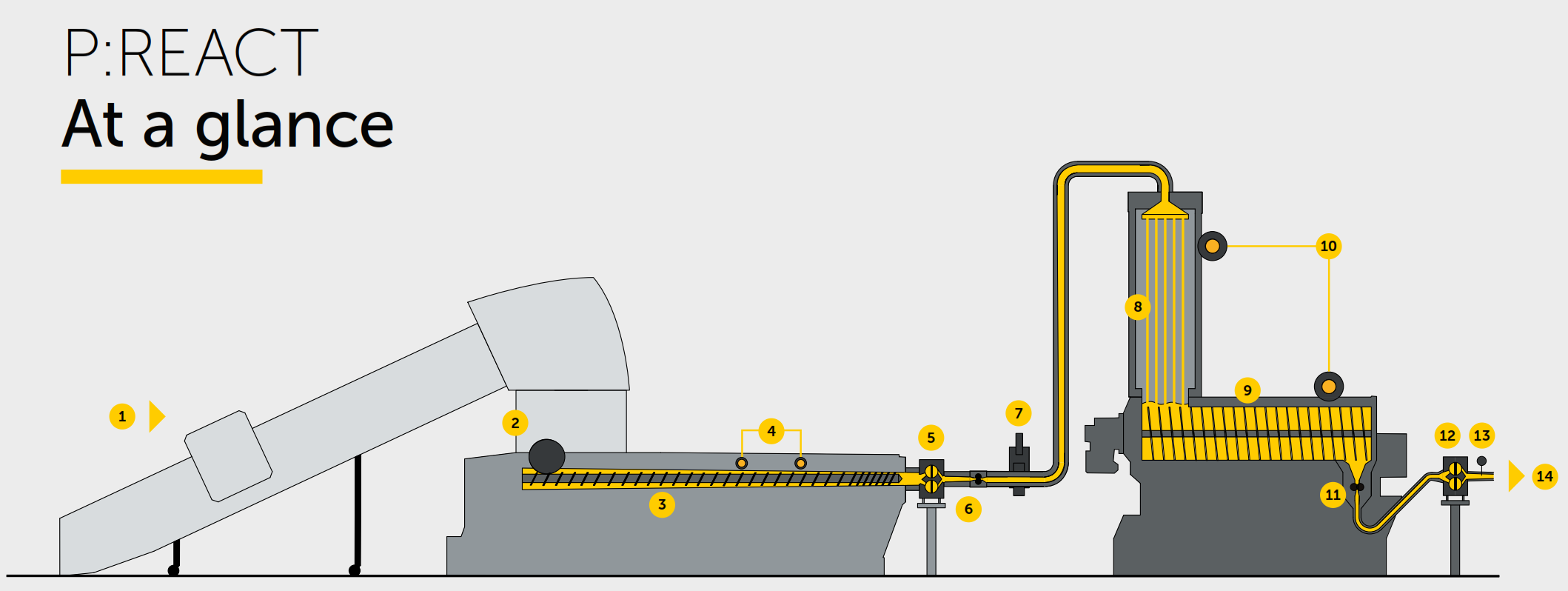

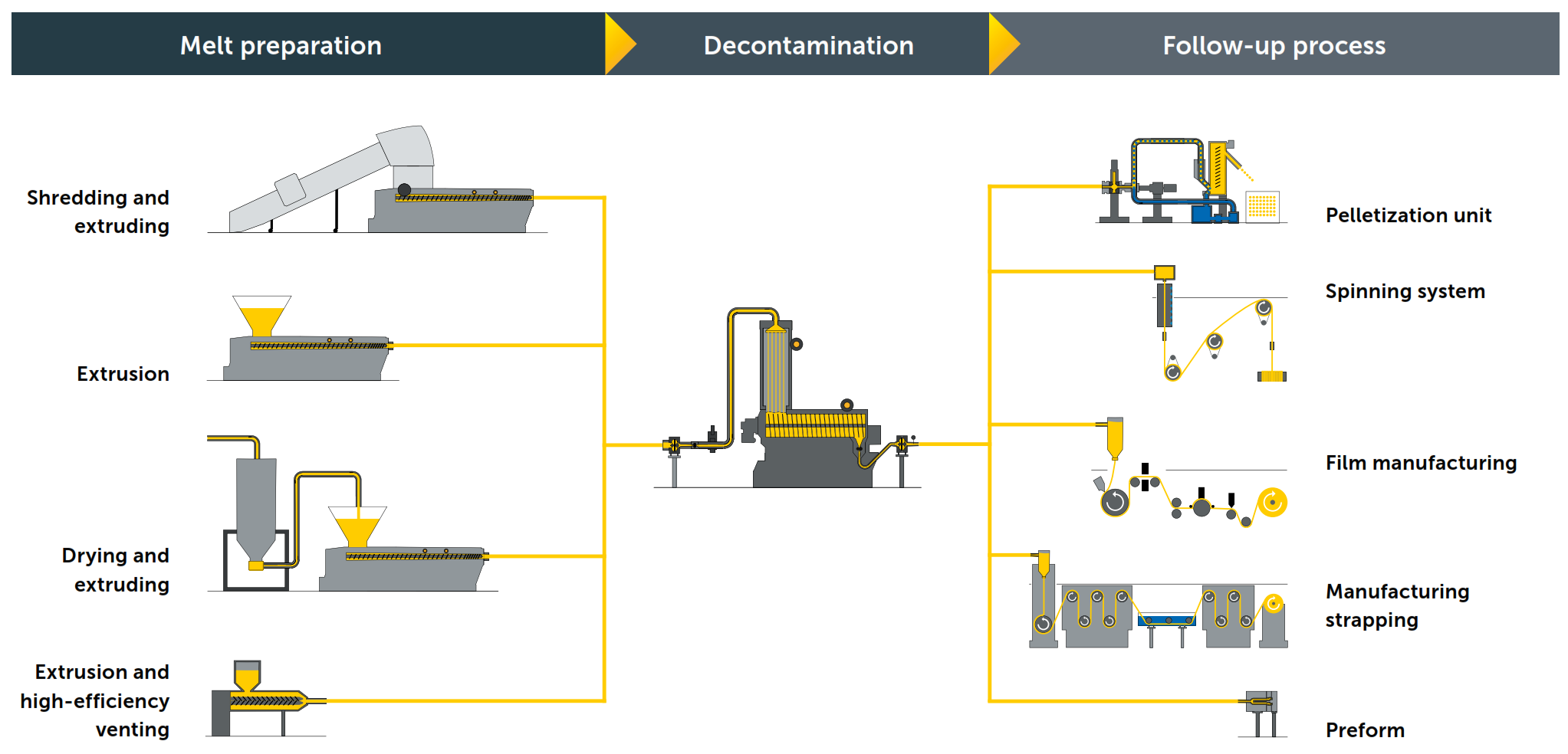

How Does The Process Flow Work for the P:REACT?

- Feeding the Material

- Conveyor belt with metal detector

- Efficient size reduction with a shredder (optional depending on material)

- Extruder to melt or plasticize the material

- Venting to remove volatile components in the melt flow

- Filtration screen changer or melt filter

- Melt pump

- Gate

- High-efficiency vacuum container (melt reactor) to remove contamination raise iV levels

- Horizontal drum for perfect homogenization

- Discharge of decontaminated substances

- Melt discharge pump

- Filtration

- Ongoing viscosity measurement

- Transfer into downstream production

What Options Are Available For The Downstream Production?

As the reactor treats the material in the liquid phase, the result out of it is an iV upgraded, iV stabilized and decontaminated PET melt, ready to be used in different downstream technologies:

A. PET Film Production to produce clam shell containers.

B. PET Fibers for textile

C. PET Straps

D. rPellets with the amazing benefits to produce consistent high quality pellets despite varied post-consumer waste. High quality rPET will command higher sell price.

This full turn key closed loop system will reduce production cost, time, and even virgin PET material makes it a win-win solution to meet strict plastic recycling initiatives.

Summary

- Approved by FDA and EFSA for 100 % food safety. LSP takes care of the contaminants in the melt phase, delivering a degree of rPET purity that is significantly higher than the current standards for food grade specified by EFSA and FDA.

- Take PET recycling at the highest level, raises and controlling IV values with pinpoint accuracy

- Melt phase eliminates issues with dust with PET bottle flake material.

- Full flexibility of infeed input material to flexibility to create several different downstream production options.

- Continuous process stability that takes a few minutes, not hours to transform contaminated PET to high-quality rPET.

- Extremely low residence time inside the reactor equates to superb energy efficiency.

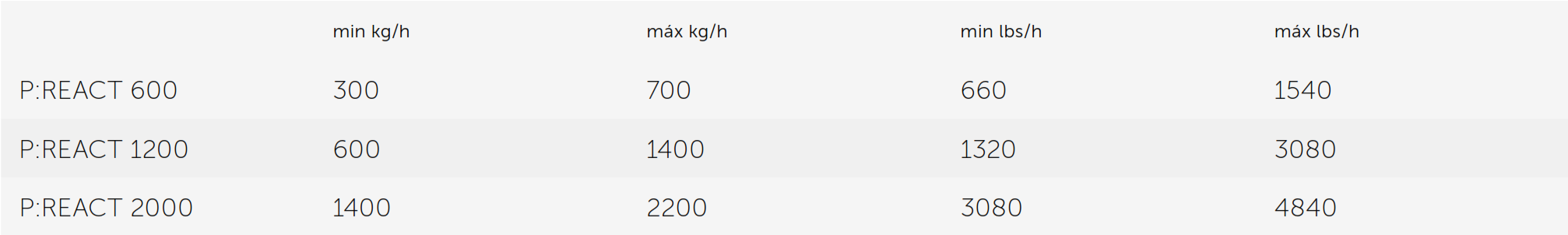

- Output rate up to 2,200 kg/h (4,840 lbs/h) depending on type

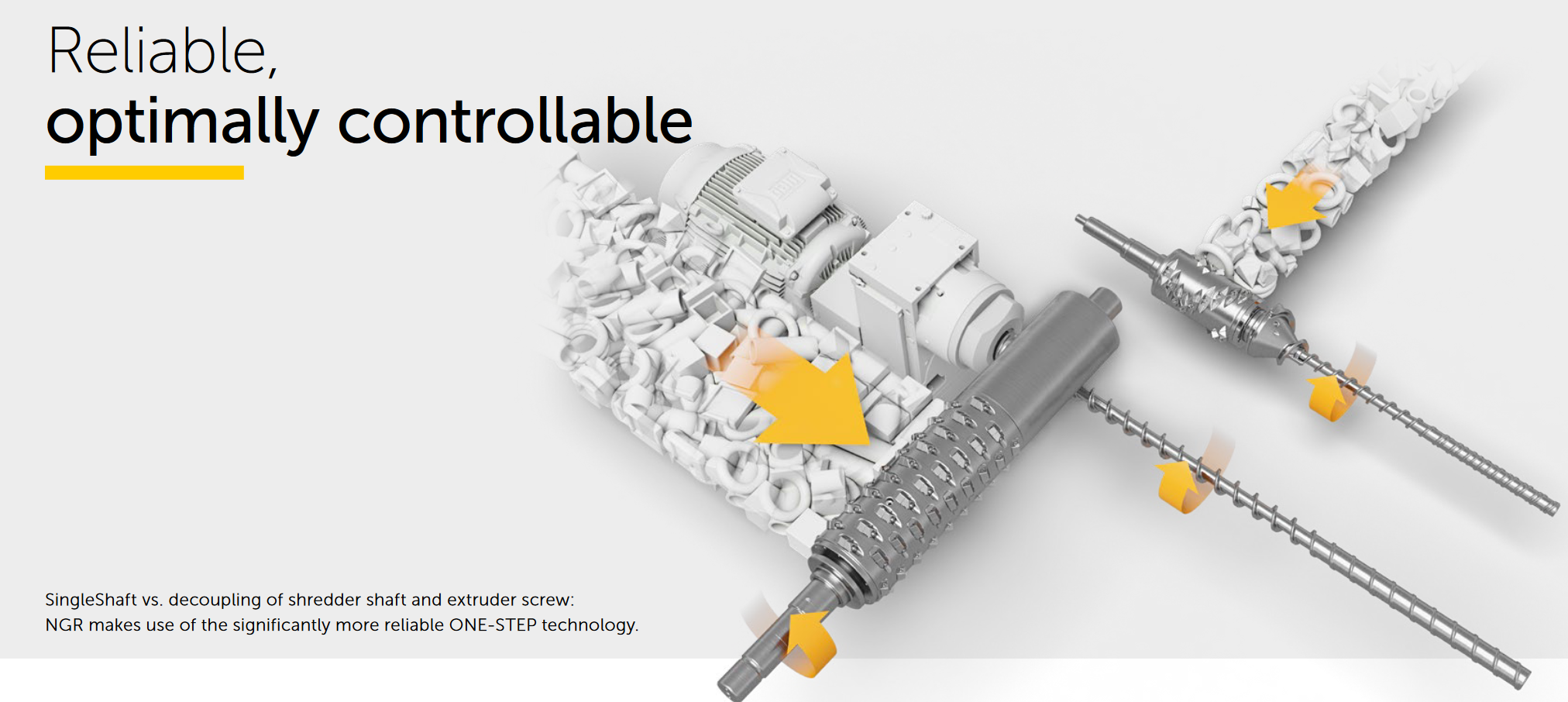

Both of these process components feature load-dependent and fully automatic control.

Both of these process components feature load-dependent and fully automatic control.