Process cooling is an essential piece of the puzzle needed for processing plastic.

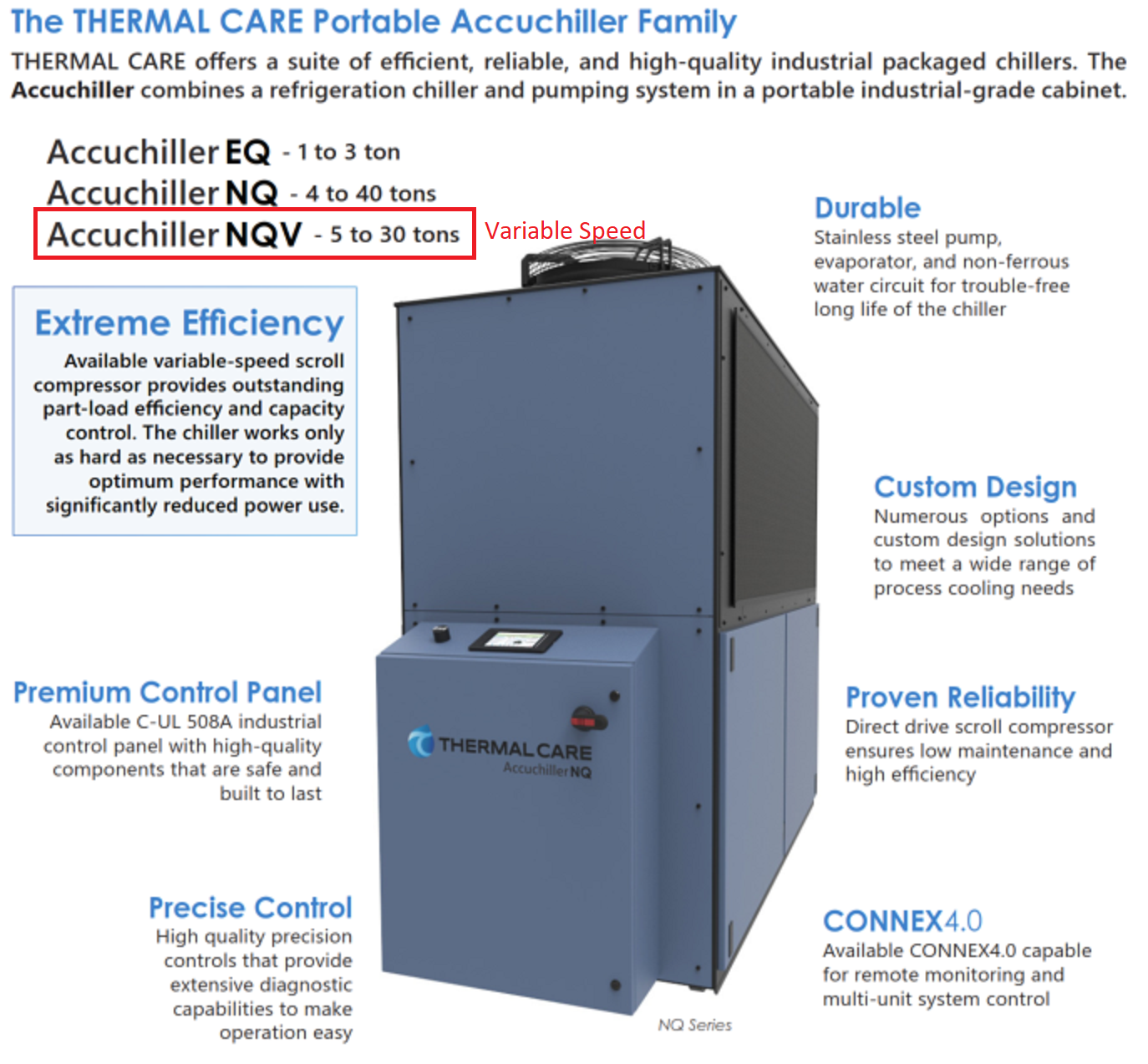

Thermal Care offers a suite of powerful and efficient portable chillers (air-cooled, water-cooled and remote condenser models) for the plastic industry. All of our units are reliable, easy to operate, packed with many standard features and built for dependable operation using an assortment of quality components. Weare proud to produce one of the best process cooling equipment systems in the industry.

A conventional portable chiller uses a compressor running at a continuous speed, also known as a fixed speed compressor. Regardless of the requirements placed on it by the process load, the compressor speed remains at 100%. Fixed speed chillers employ a “hot gas bypass” to maintain the demand on the compressor to avoid wide fluctuations in the coolant temperature delivered to the process for consistent output.

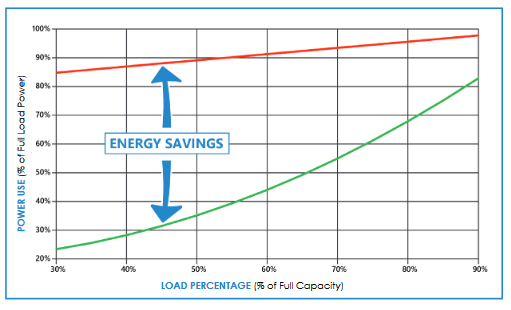

Compared to a typical chiller with a fixed speed compressor, the Thermal Care NQV series chiller with a variable speed compressor provides major power savings at partial loads. This is particularly important in process applications which run varying loads that rarely use full capacity of the chiller. Variable speed scroll compressor technology varies the compressor speed to match the process load. This means the compressor slows down under part load conditions for peak performance and reduced power use.

Why go for the variable speed compressor chiller?

- You Want To Save Money On Energy Costs

The variable speed scroll compressor technology, in conjunction with the PLC, constantly monitors the process and adjusts the compressor speed for peak efficiency and temperature control. Since the compressor speed is automatically adjusted, the chiller works only as hard as necessary to provide optimum performance with significantly reduced power use. Studies have shown that a 20% reduction in motor speeds can lead to 51% in energy savings.

The variable speed scroll compressor technology, in conjunction with the PLC, constantly monitors the process and adjusts the compressor speed for peak efficiency and temperature control. Since the compressor speed is automatically adjusted, the chiller works only as hard as necessary to provide optimum performance with significantly reduced power use. Studies have shown that a 20% reduction in motor speeds can lead to 51% in energy savings.

Typical ROI on variable speed compressor chiller = 12 ~ 18 Months

NOTE: IF your heat load regularly operates well below the chiller’s available capacity, the NQV chiller with a variable speed compressor would be extremely efficient in energy savings.

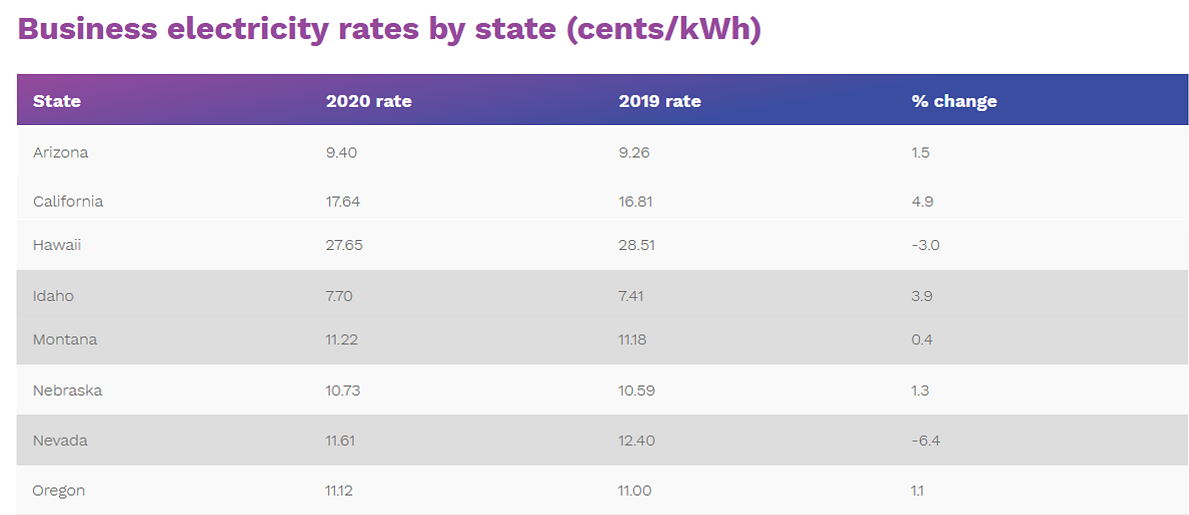

**Variable Speed Portable Chiller Savings Calculator**Below is a chart of the electricity cost for the Western States that Hirate America covers.

Reference: Choose Energy Electrical Rates By States

Reference: Choose Energy Electrical Rates By States - You Want to Save Money On Installation

Portable chillers are fully packaged systems housed in a single cabinet with mounted casters. They come with an integral tank and pumping system containing everything you need to provide chilled water to your process. It’s a complete plug and play setup, which makes installation super easy. Just place in your desired location, connect the water and power and you’re ready to go.

Portable chillers are fully packaged systems housed in a single cabinet with mounted casters. They come with an integral tank and pumping system containing everything you need to provide chilled water to your process. It’s a complete plug and play setup, which makes installation super easy. Just place in your desired location, connect the water and power and you’re ready to go.

This also provides flexibility on production as you can move the chiller from one machine to another with ease. - You Want Smart Technology That Saves Time

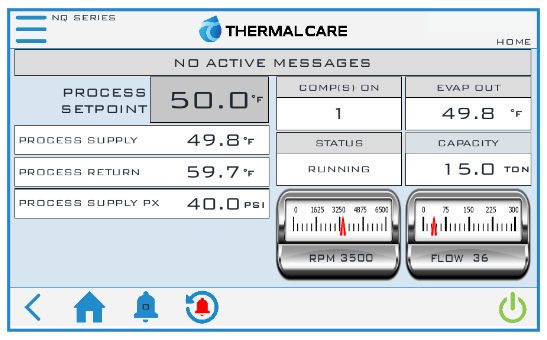

The NQV series portable chiller come standard with Thermal Care’s latest 7″ color touch screen with advanced PLC controls that provides real time diagnostics. This enables you to troubleshoot and solve issues quickly, which saves valuable time and headaches. This feature is a maintenance crew’s dream come true.

The NQV series portable chiller come standard with Thermal Care’s latest 7″ color touch screen with advanced PLC controls that provides real time diagnostics. This enables you to troubleshoot and solve issues quickly, which saves valuable time and headaches. This feature is a maintenance crew’s dream come true.

Optional CONNEX4.0 technology allows remote monitoring and multi-unit system control with secure access and control to all your Thermal Care connected equipment so you can have confidence your process is running without issues.

Featured Specifications

Hirate America partners with Thermal Care, a leader in manufacturing of industrial grade water chillers, process cooling equipment and systems for applications worldwide. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in offering both standard and custom designed industrial process cooling solutions.

If you have any questions regarding portable chillers, please contact any of the Hirate America team members to provide a process cooling solution tailored to your requirements.