Motan unveils their latest product Swift sCompact, dry air dryer with integrated conveying unit.

Brand New Product: Please contact us directly to get more details on Hirate America special promotion or click the link below.

The new swift product family comprises the most cost-efficient models of the Motan product portfolio. swift products are quick and easy to operate. Whether for standardized injection molding, blow molding, or extrusion applications – they are always the right choice. The swift product family not only represents value for money, quick delivery and our usual Motan quality, but also state-of-the-art control technology.

Drying With Desiccant Beds

The sCompact dryers are developed especially in order to guarantee a stable and reliable drying process. The two desiccant cartridges generate a continuous dry air flow with low dew point and are perfectly suitable for production facilities with high air temperatures and high ambient humidity.

Each dryer is equipped with two large fully insulated stationary desiccant beds

The benefits:

-

-

-

-

-

-

-

-

- high mechanical and chemical stability

- ensures reliability and guarantees constant and stable dry air quality with low dew point

- rapid dehumidification of the desiccant cartridge in the regeneration phase due to closed loop during cool down phase and as the regeneration air flows in the counter direction

- saves energy

-

-

-

-

-

-

-

Water Cooler & Compressed Air

The dryer is able to achieve very low and consistent dew points because:

-

-

-

-

-

-

-

-

- It cools the return air from the drying bin and the regeneration air in the closed loop cool down phase

- The unit uses dry compressed air when regenerating the desiccant bed.

-

-

-

-

-

-

-

Drying Bin

-

-

-

-

-

-

-

-

-

-

-

-

-

- Sight glass and easy-to-open quick release handles

- Door design integrated into the bin geometry to optimize material flow and to simplify cleaning

-

-

-

-

-

-

-

-

-

-

-

-

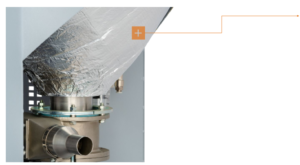

Fully Insulated Drying Bin

Fully insulated drying bins

Insulation of entire drying bin including material outlet guarantees stable drying conditions and saves energy.

Air Diffuser Cone

The optimum geometry of drying bins and cleverly designed air diffusers are guaranteeing

correctly dried material is delivered to your processing machine.

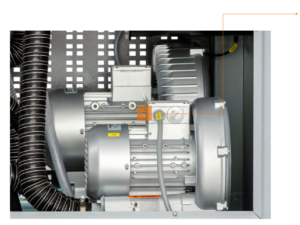

Drying & Conveying Blowers

Side channel blower for integrated conveying and drying

The benefits:

-

-

-

-

-

-

-

-

-

-

- simple, quiet and compact design

- perfect for moderate distance conveying applications

- produces a reliable vacuum power

- IE3 motors for all blowers with 0.85kW and larger

-

-

-

-

-

-

-

-

-

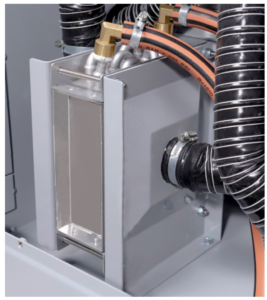

Dry Air Conveying & Line Purging

Maintaining material temperature and eliminating re-absorption of moisture due to:

-

-

-

-

-

-

-

-

-

-

- dry warm air is used for transporting the material to the processing machine.

-

-

-

-

-

-

-

-

-

Stainless steel suction box with integrated purge facility:

-

-

-

-

-

-

-

-

-

-

- guaranteeing perfectly conditioned material is conveyed directly to the processing machine.

-

-

-

-

-

-

-

-

-

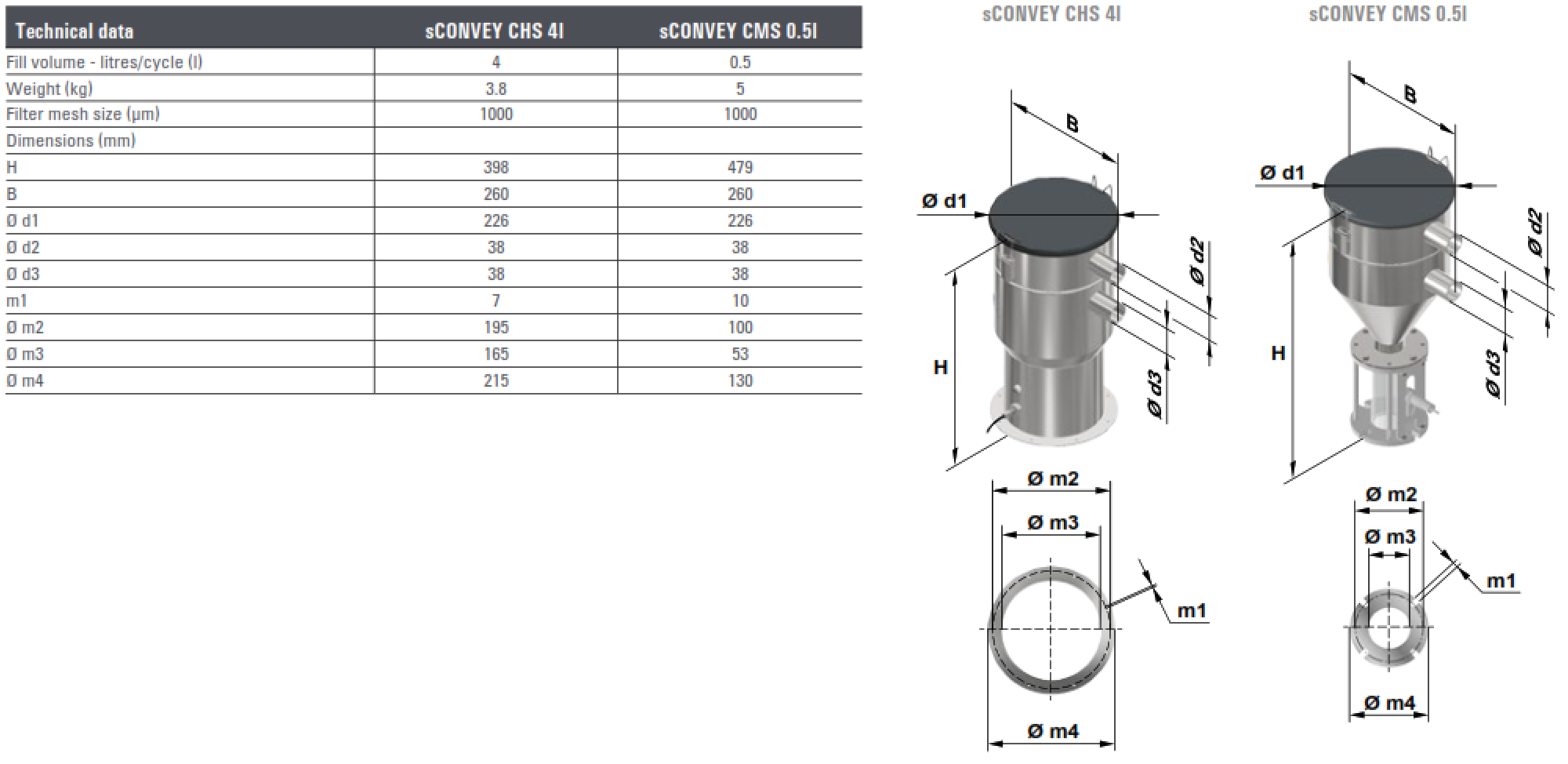

Conveying

The integrated sConvey CHS loader is used to transport plastic granulate quickly and without contamination to the processing machine or the drying bin. Costly down times are avoided by precisely coordinated material conveying to the processing machine. This prevents material loss and the production area remains clean and safe. When conveying hygroscopic materials with small throughputs or where space is limited space is limited a sConvey CMS machine loader version with 0.5L is available. The discharge module of the loaders has no discharge flap and the unit must be mounted directly on the feed throat of the processing machine.

-

-

-

-

-

-

-

- sConvey CHS loaders are used to convey the plastic granulate quickly and cleanly to the processing machine or drying bin.

- The loader vaccuum valves are located in the dryer.

- Material is delivered exactly when needed, keeping machines running and avoiding costly downtime.

- As option a machine mounted loader CMS 0.5L is also available.

-

-

-

-

-

-

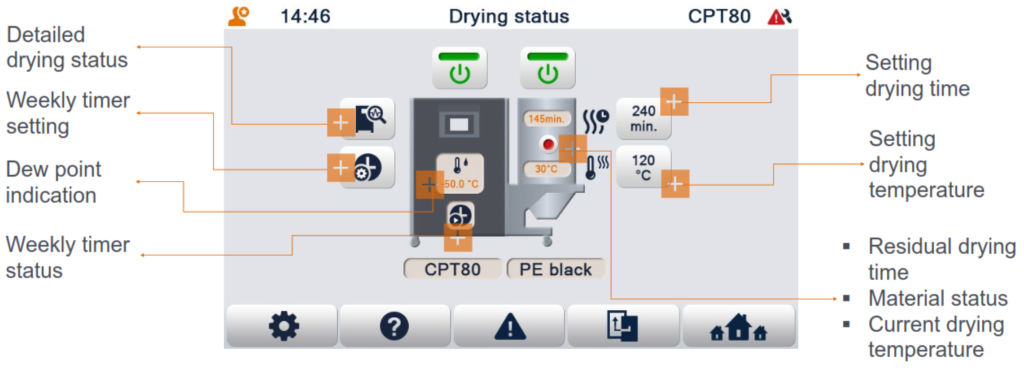

sCompact control

The microprocessor control of the sCompact uses both SSR and PID technology in order to ensure a precise drying temperature. The control manages a dry air generator, a drying bin and up to 3 hopper loaders. Thanks to a modern 7″ touch screen color display, all conveying and drying functions can be shown and monitored in a user-friendly way. The control offers a choice of 16 user interface languages. The dryers are equipped with a dew point control for accurate drying and reduction of the energy consumption. They are also equipped with a conveying line purging function. The sColor V dosing unit with two dosing modules can be optionally controlled at the sCompact control. Thanks to the integrated conveying and mixing function in the sCompact control, you will save money as no separate control is needed.

-

-

-

-

-

-

-

-

- User friendly and snappy 7″ touch screen display

- 128MB RAM, 128MB Flash

- Intelligent maintenance reminder

- 16 languages

- Dew point control

- Line purging

-

-

-

-

-

-

-

Controls – Overview

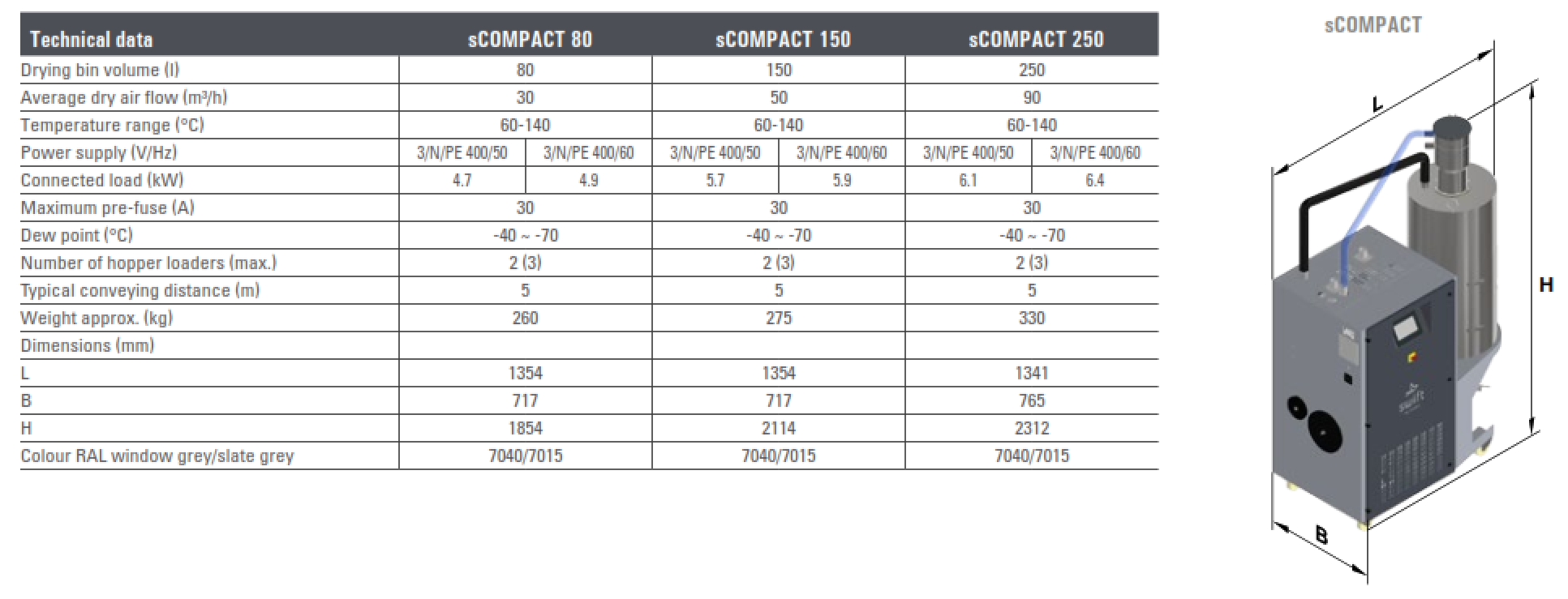

sCompact 80 / 150 / 250 Technical Data

Currently there are 3 sizes available, 80L, 150L and 250L drying bins and a hopper loader with a capacity of 4 liters.

NOTE: sCompact 250 can supply two processing machines.

Hirate America partners with Motan who develops modular units and well thought out systems for the manufacturing and processing of plastics. Our product lines cover the entire spectrum: dosing & mixing, drying, crystallizing, conveying and storage as well as the corresponding control and automation technology. As a specialist for material management and a leading global provider in the plastic manufacturing and processing industry, we have unique know-how on all areas of materials handling and logistics management.

We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

If you have a project that you would like to discuss, feel free to contact us below to schedule a free consultation.