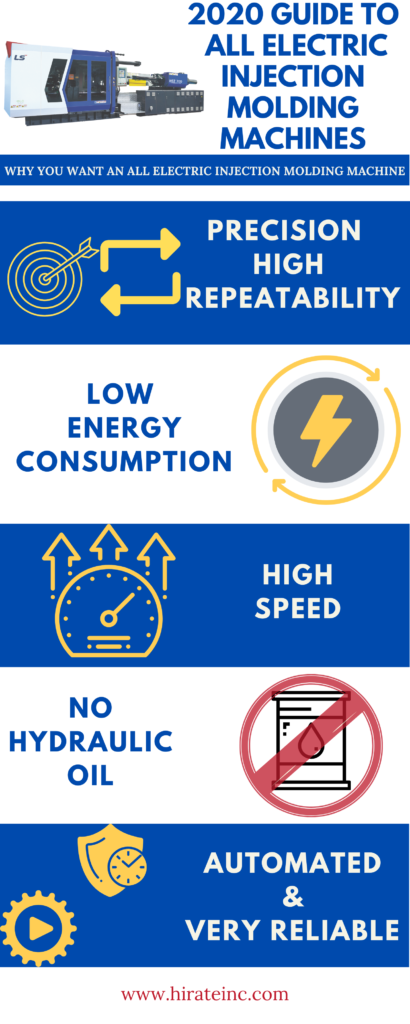

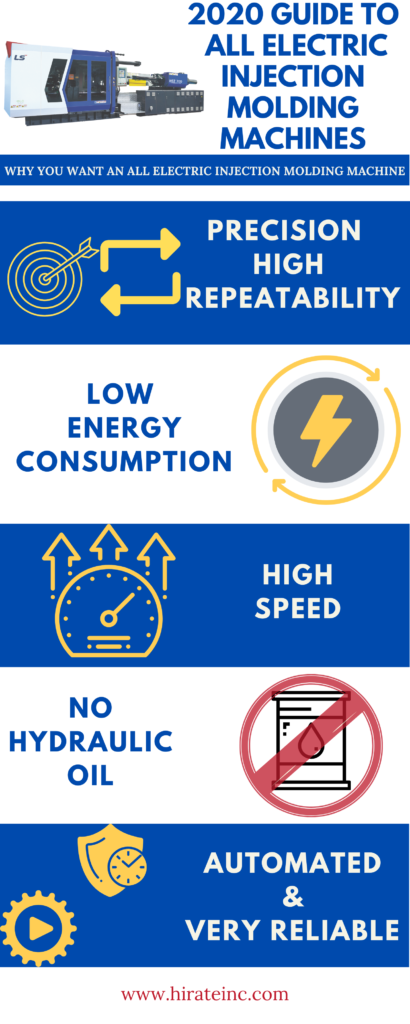

All electric injection molding machines have been on the market for decades now, and there are many benefits in utilizing all electric injection molding machines. Although there are still applications for standard hydraulic and hybrid injection molding machines, many of the major injection molding machine manufacturers are primarily focused on manufacturing all electric molding machines. This is especially so as technology is constantly advancing and the previously too expensive to build larger tonnage all electric molding machines are becoming more and more common. It is clear that the future of the industry is in all electric injection molding machines.

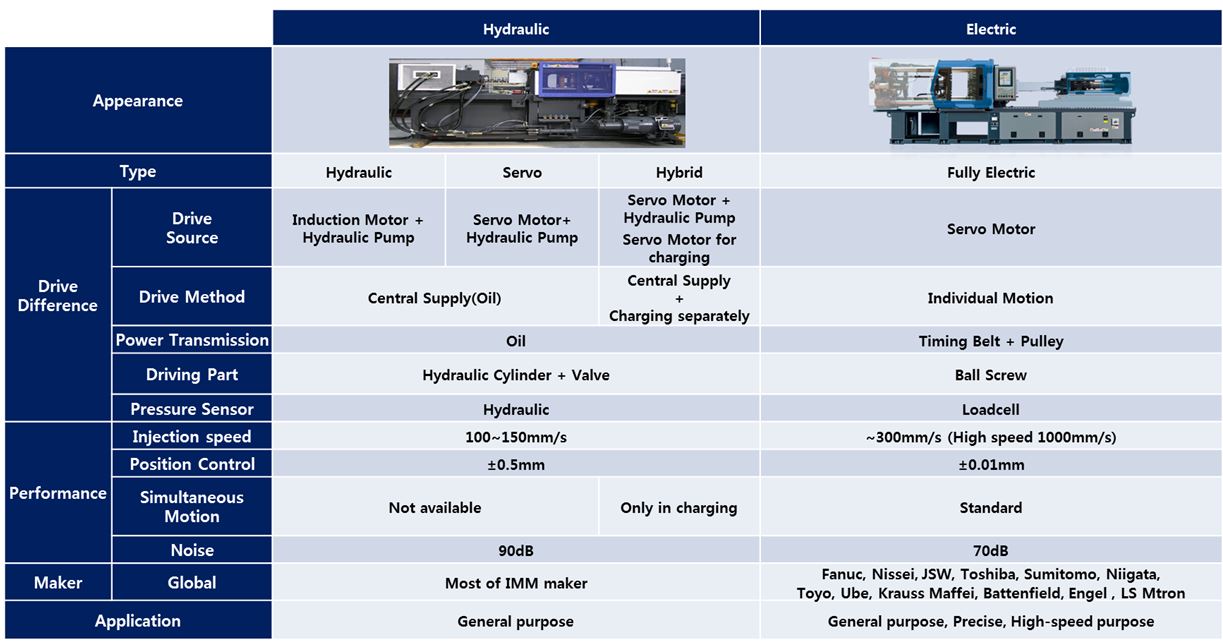

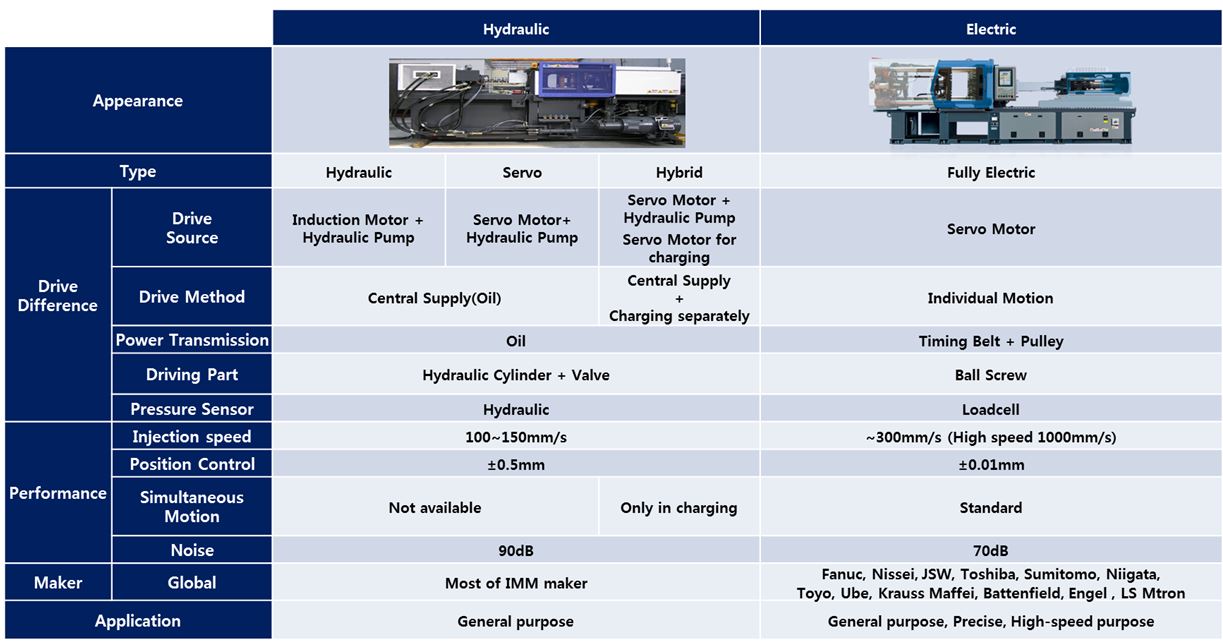

What is the difference between an all electric injection molding machine and hydraulic injection molding machine?

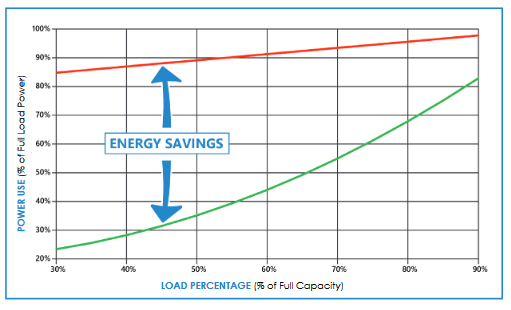

Electric injection molding machines consume energy only when required for a given action, and motor output is matched to meet requirements, unlike traditional hydraulic injection molding machines which use continuously consume energy even while idle.

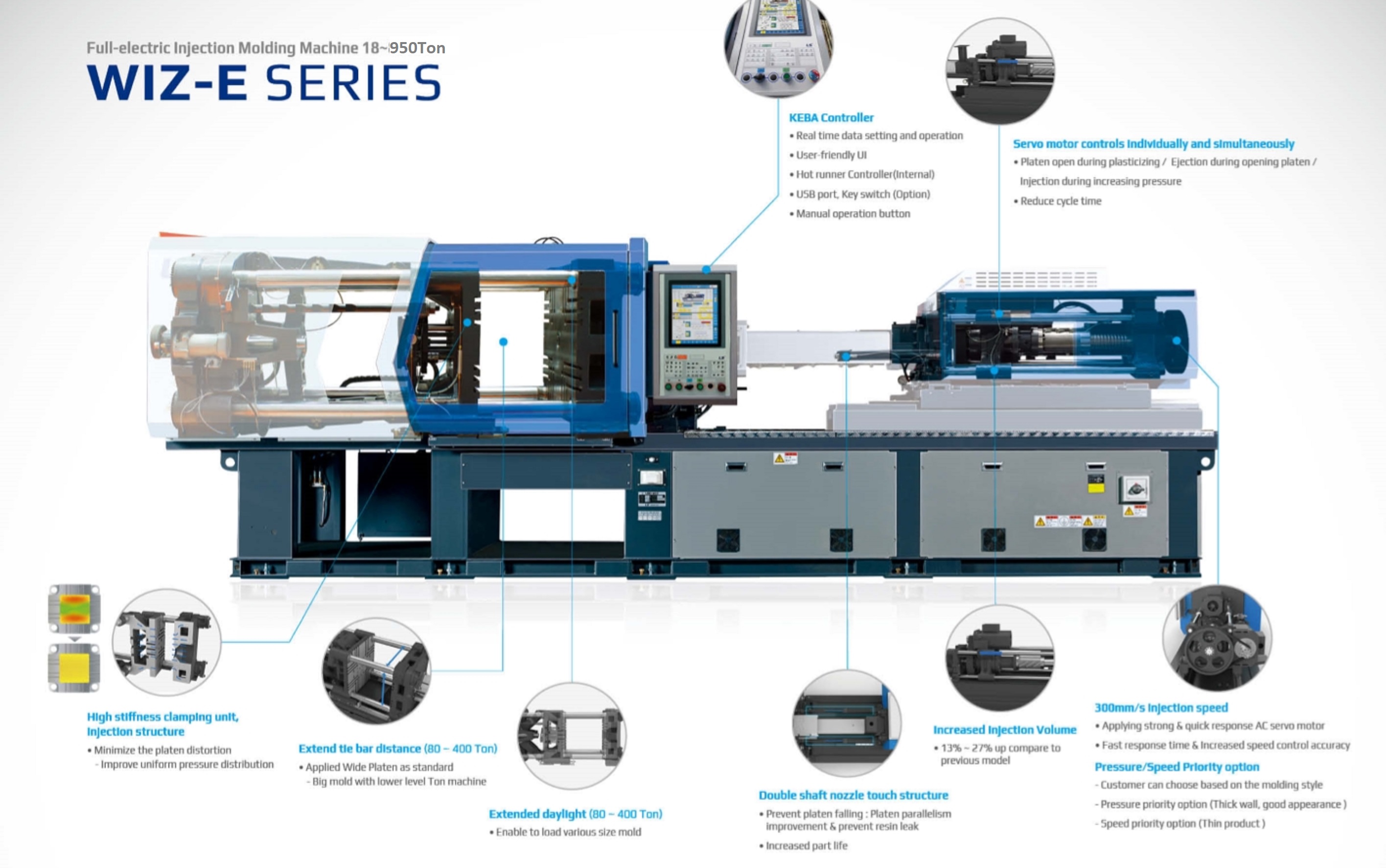

Instead of being driven by a hydraulic system, electric injection molding machines are digitally controlled with high-speed and highly-efficient servo motors to drive the whole process. Each axis is controlled by an independent motor for injection, extrusion, clamping and ejection.

The outcome brings about a faster, cleaner, more repeatable and energy efficient injection molding process. Energy consumption for electric injection molding machines can be reduced by 50 to 75% compared to a hydraulic type.

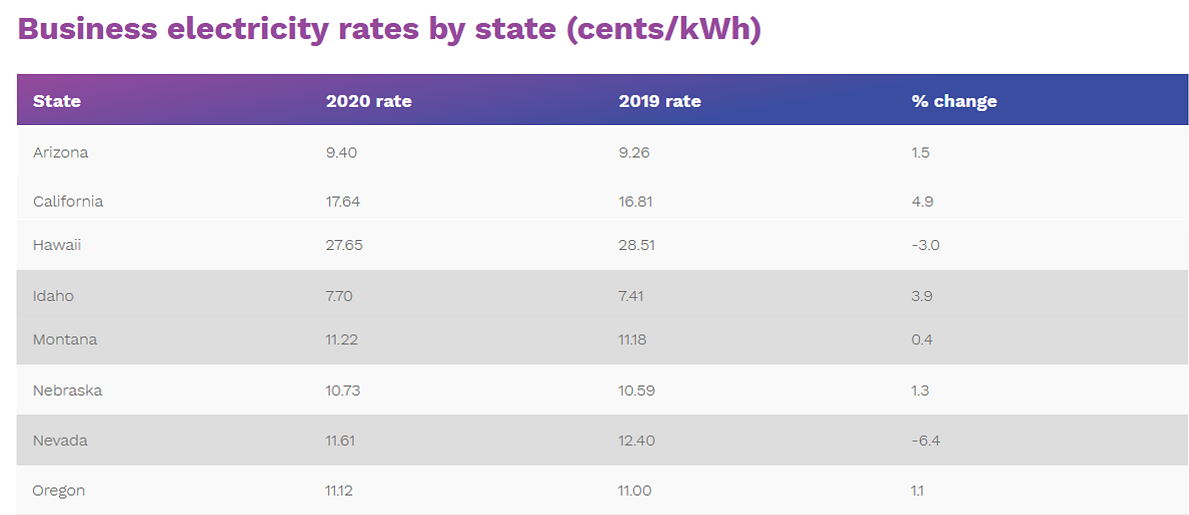

Due to a recent rise in electricity bills in the industry, all electric injection molding machines have become more popular to save electricity costs ultimately leading to overall operational cost reduction.

What are the best applications for an all electric injection molding machine?

All electric injection molding machines are currently being applied to various industries such as automobile parts, medical supplies, medical equipment, electronic parts, household appliances, lens molding, and daily necessities.

If your products require high product quality, precision and high repeatability then all electric would be the way to go.

High Repeatability and Precision (Closed loop controls and linear motions)

- Accuracy

Of the 3 types of molding machines, all electric injection molding machines have the highest accuracy and repeatability. This is because of the fact that these machines use electric servo motors with a 0.1mm +/- rotation to actuate their movements. This type of movement allows the process to completely negate the fluctuations and inaccuracies of movements actuated by hydraulic pressure and their unavoidable pressure curves.

- Consistency In Production

Standard hydraulic injection molding machines constantly experience variations in their process throughout the year, and even throughout the day. This is because the weather is always changing and has an effect on your machines temperature and humidity. As hydraulic oil gets cooler, its viscosity increases, and as hydraulic oil gets warmer, its viscosity decreases. The way hydraulic oil performs also changes as it degrades over time. This means that the way the oil in a machine moves and lubricates will always eventually be totally different than day 1.This also means that your molding machine’s process may need to be adjusted periodically throughout the day. Standard hydraulic molding machine controls are considered “open loop” because they send signals to valves to adjust pressures, but don’t actually have direct control over the physical movements of the machine, and thus cannot make all of the minor adjustments that an all electric machine can make in real time. All electric injection molding machines are considered to have “closed loop” controls because they control every movement with physical gear turns of their servo motors, and have the ability to constantly monitor and control their positions and speeds to a very tight tolerance, regardless of the ambient conditions. This is the difference between “closed loop” and “open loop” controls.

All electric injection molding machines are the perfect fit for manufacturing most complex, difficult, and thin walled parts. You can inject very accurate shots, while maintaining precise repeatability through the day, night, and seasons.

You Want Low Energy Consumption To Save On Power Costs

Low Energy Consumption

Contrary to its name, electric injection molding machines are extremely energy efficient. If you compare typical hydraulic injection molding machines and electric injection molding machines in terms of the same part and mold, you will see 50% to 70% energy savings in most applications of electric machines.

In a typical hydraulic injection molding machine, a hydraulic pump is constantly on when the machine is running. It has to keep running to circulate oil and is generating heat as long as the machine is running. On the other hand, an electric injection molding machine only consumes electricity as a servo motor turns to actuate movement, so much of the production cycle is spent idling, this is especially so in case of the cooling phase of cycle.

Electric Servo Motors

Electric Servo Motors

Typical hydraulic injection molding machines have one or more pumps that generate hydraulic pressure, and valves that direct pressure to hydraulic mechanisms to build pressure based on the necessary movements. Electric injection molding machines do not have a central electric motor, but use individual electric motors designed for each function that is needed throughout the machine, i.e. mold open/close, injection, recovery, and ejection. This means that the motors can be idle until their specific function is required. This is day/night comparison with a typical hydraulic injection molding machine that has to run its pumps continuously, even when nothing is happening. This is especially apparent during the cooling phase.

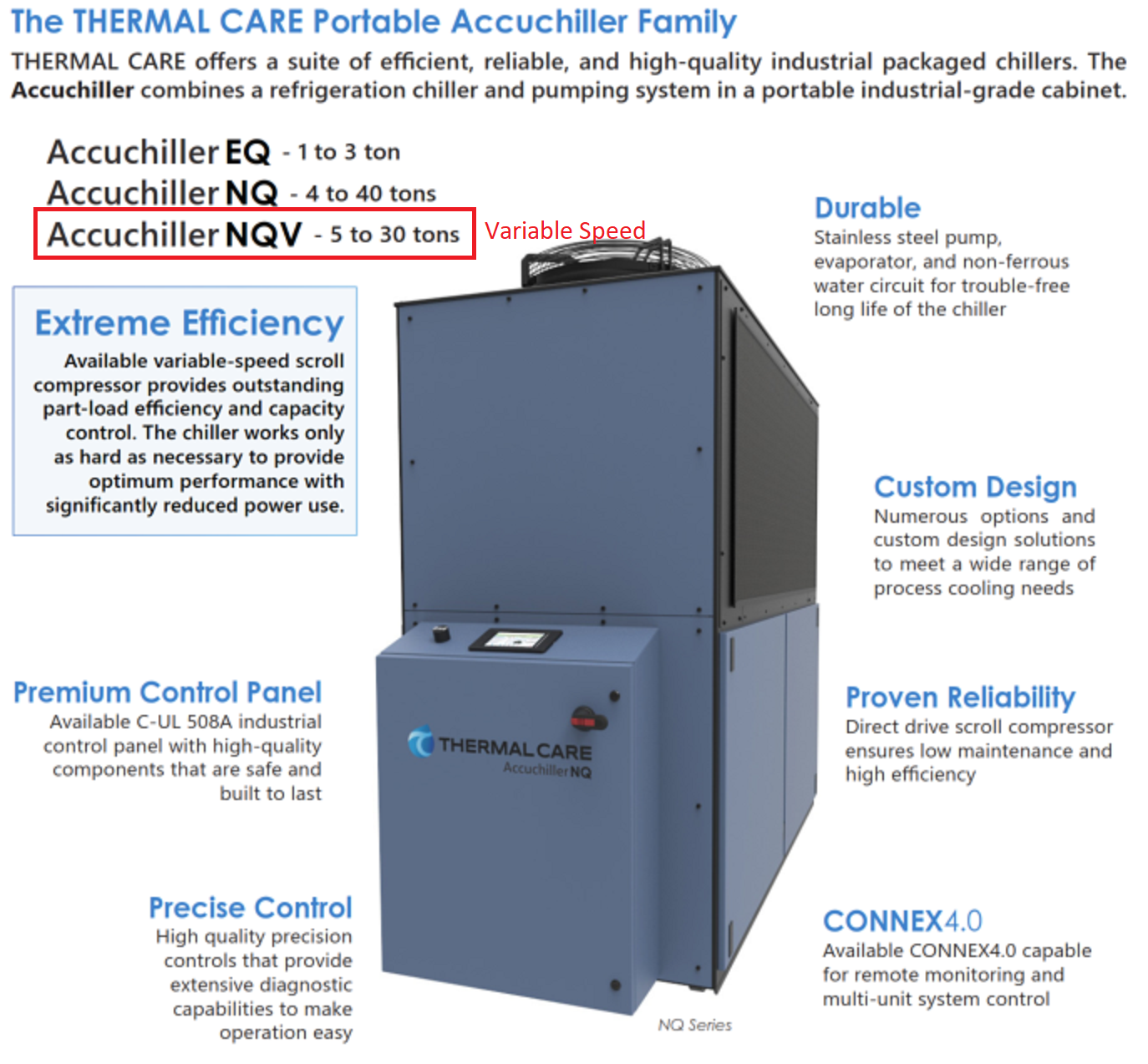

No Hydraulic Cooling Needed

No Hydraulic Cooling Needed

Energy savings don’t end with an injection molding machine. The elimination of hydraulic pump circuit also doesn’t have a need for cooling hydraulics. Since electric injection molding machines don’t have hydraulics, they don’t require machine cooling. The only cooling that you will likely need is for your mold and feed throat. This leads to additional savings as you will not need additional water lines. Chillers also consume large amounts of electricity, and cooling towers consume water and electricity and require frequent maintenance and monthly water treatment plans.

Less Equipment Equals Less Maintenance

Less Equipment Equals Less Maintenance

It is very common for customers who use only electric injection molding machines to only have chillers in their plant. This is because they no longer have a need for the high temperature circuit of cooling (85-95F) for their machines but only require the low temperature circuit of chilling (anything under 80F, usually 55F) for their molds and feed throats. Having fewer pieces of equipment obviously means, less capital invested, less upkeep and maintenance costs, less energy consumed, and lower overhead costs.

Overall Plant Energy Savings

Electric injection molding machines also run significantly cooler because there is no heat being generated by a hydraulic pump. Medical and clean room molding facilities are often climate controlled, which means that an air conditioning system does not have to work as hard to remove the heat from a molding room, if the machine is electric. This is another reason why many medical and clean room manufacturers exclusively use electric injection molding machines.

Think Long Term Savings

Think Long Term Savings

Based on all of the above points, when comparing a 390-ton typical hydraulic injection molding machine vs. an electric injection molding machine, there is around $17,000 of annual savings on the electric machine. This number represents the savings based on today’s factors, but it is only expected to increase as long as energy costs all across the U.S and Mexico are constantly on the rise. With proper maintenance and care, quality injection molding machines should last 20+ years. This means that when considering a new injection molding machine, you need to think of 10 to even possibly 20 years down the road. Make sure to purchase your new machines from a reputable and established company who manufacturers their own components, such as platens, motors, sensors, breakers, contactors, cables etc. This ensures that you will always have access to replacement parts. LS Mtron is one of the billion dollar companies that manufacture all sorts of major components for their machines in house.

You Want A High Speed Molding Machine

- Simultaneous Movements

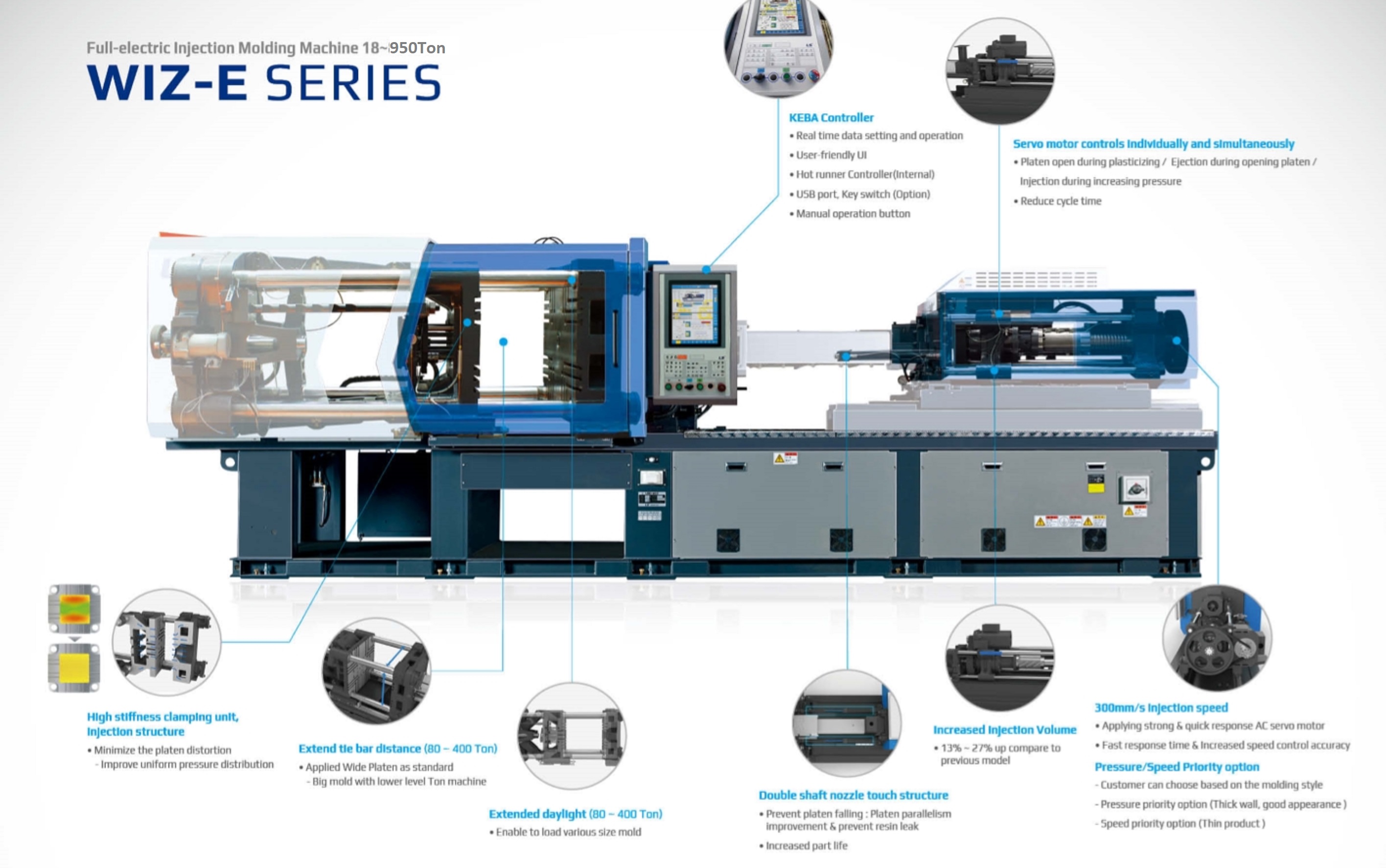

All electric injection molding machines have multiple electric servo motors. These motors are coupled to pulleys and belts that work onto ball screw mechanisms that actuate the movements of functions, i.e. platen open and close. The ability all electric machines have to make compound movements (actuating multiple functions at the same time) is one of the reasons why electric machines often times produce reductions in cycle time vs standard and hybrid injection molding machines. You can “eject on the fly” or eject your parts before opening the mold completely,and you can start recovering the screw while opening and closing the mold. Hydraulic injection molding machines can only handle one movement at a time, because they typically only have one hydraulic pressure circuit to actuate movements. This becomes a huge game changer for many molders when they decide to advance to all electric injection molding machines.

- Instant Torque

We all know that electric cars get their immense speed from having instant torque from their electric motors, and the same goes for our all electric injection molding machines. They have instant linear motions from our AC electric servo motors, and can achieve up to 800mm per second injection speeds, and can also have multi-step injection speeds with our high output and high response AC servo motors.With all that instant torque also comes the need for a very rigid and robust toggle clamping mechanism. LS Mtron utilizes a very rigid 5 pin toggle mechanism to ensure that you will continue to have a fast and reliable machine. Our platens and toggles have gone through extensive FEA (Finite Element Analysis) to determine where all of the major stress points on the mechanisms are. We also utilize the highest quality steel and casting technologies via our own inhouse steel forging division. All of this is done to maximize the lifetime of our all electric injection molding machines.

We also utilize a very robust and precise ball screw mechanism to actuate the clamping motion. As is with any machine component, the range of performance and quality can range drastically, so it is important to ask what manufacturer’s ball screw the injection molding machine you are looking at uses to fully understand its reliability of performance.

You Don’t Want To Deal With Hydraulic Oil

- No Oil Equals No Mess

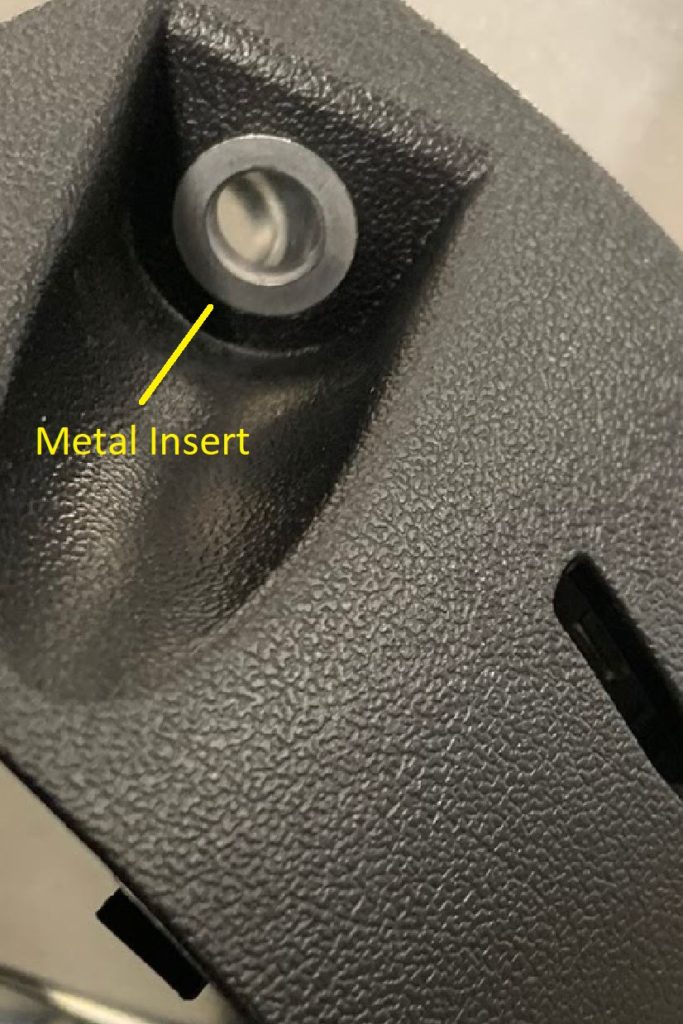

Injection molding machine types are categorized into hydraulic, hybrid, and electric injection molding machines. Typical hydraulic and hybrid injection molding machines require hydraulic oil to actuate the clamping motion and injection unit of a molding machine. Electric injection molding machines use servo electric motors to actuate all of the machine motions without hydraulic oil.Electric injection molding machines have no risk of oil leaks because they don’t use oil. Your manufacturing site will be free of dirty and slippery oil leaks which are a huge safety hazard during mold changes. Not to mention you will no longer have to replace hydraulic oil after 2 to 5-year lifecycle of oil. The lifecycle of oil depends on whether you run 24/7 and whether you keep oil temperature hot, which accelerates degradation. Using hydraulic oil is significantly different from not using it. You never want to have oil contamination and damage your production site, but this may become a serious problem in the case of food packaging, medical molding or clean room required industries.

- No Oil Changes Equal Less Maintenance

The life cycle of the hydraulic oil in a machine depends highly on the hours of use and the quality of the machine itself. We have seen some instances where the hydraulic oil became extremely contaminated in as little as 6 months of use on a competitors brand new machine. Imagine having to replace oil every 6 to 12 months, not to mention the cost of the oil which can get relatively expensive with larger machines requiring over 500 gallons of hydraulic oil. With our hybrid injection molding machines, we have seen some of our customers, who periodically test the quality of their hydraulic oil, get 5 or more years of use out of their hydraulic oil. However, please note that the manufacturer does recommend that the hydraulic oil be changed every 3 to 4 years depending on the hours of operation.

The clean and quiet working environment that you get with all electric injection molding machines make them the ideal machine to use for food packaging and medical molders. You won’t have to worry about getting oil contamination when cleaning your facility before a plant audit and sending your customers contaminated parts.

Think of all electric cars not needing any oil and almost no maintenance needed, it’s the same with all electric injection molding machines.

Technology Advancements

- Extremely Reliable

All electric injection molding machines are the most reliable of the different types of injection molding machines. This is because unlike standard hydraulic injection molding machines and hybrid injection molding machines that were designed many decades ago, and are often more geared for a lower price bracket, all electric injection molding machines typically use state of the art technologies available. All electric injection molding machines are also very quiet while running, and most run at or below 70db. This means that your employees are not required to wear hearing protection while operating the machines.

You will have no oil, less maintenance, more accuracy, higher repeatability, energy savings, a much quieter work environment and a machine that is easier to maintain to continue running production.

- Automated Features

With all electric injection molding machines you will have no sticking valve issues, degrading oil quality issues, ambient temperature process fluctuations and noisy pumps.Many of the all electric injection molding machines have safety features standard, like mold safety to prevent crushing parts and foreign objects in the mold, cold screw rotation prevention to prevent the mistake of accidentally rotating the injection screw when the plastic is still cold and solidified from the machine being idle.Most machines will have a centralized lubrication system or automation lubrication system to automatically pump grease onto the tie bars, toggle links, linear guides and other locations where greasing is necessary. So as long as the grease reservoir or cartridge is full, the injection molding machine will automatically grease the areas that need lubrication based on the number of full cycles. When the grease levels are low, some machines have sensors to alert that the grease reservoir or cartridge levels are low to remind your maintenance team to refill grease or change the cartridge.

Conclusion

Many of our customers prefer All Electric Injection Molding Machines based on the following:

- The highest degree of cleanliness

- Very low energy consumption

- Very high repeatability and precision

- High speed molding

- Technological Advancements and Features

For these reason an all electric molding machines are extremely reliable for long term production runs.

We always recommend LS Mtron’s all electric injection molding machines when customers want to make millions of parts reliably every year. If it’s a 24/7 operation that is required for maximum production rates, this is the best type of molding machine money can buy. We have customers that run “lights out” without any personnel on-site outside of normal business hours and weekends without any downtime.

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

If you have a project that you would like to discuss, feel free to contact us below to schedule a free consultation.

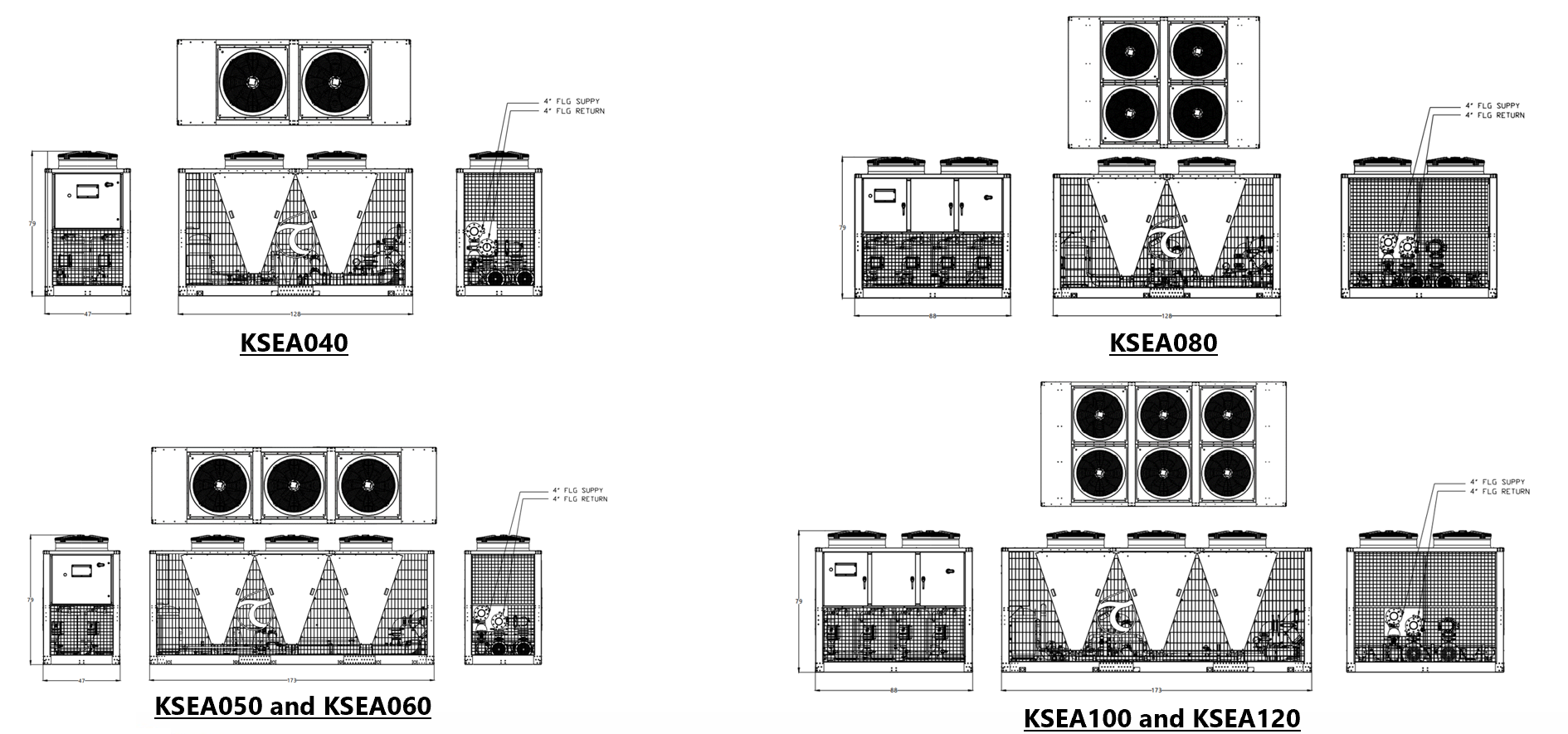

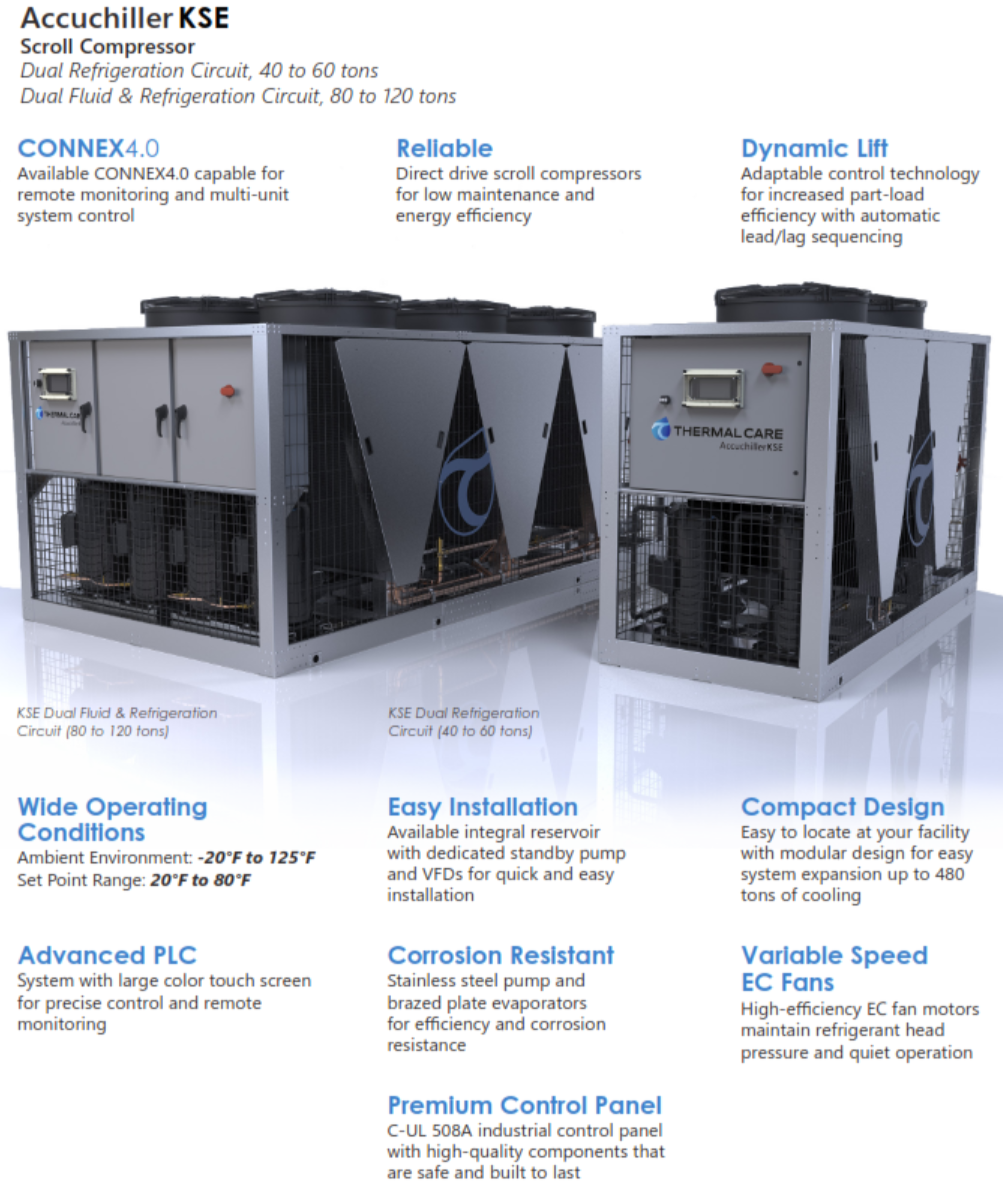

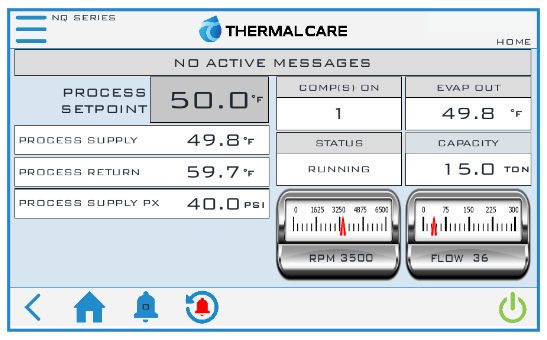

The modular design of the KSE unit allows up to 480 Tons of cooling. Each of the units provides dual refrigeration circuits. With the 80, 100, 120 ton units they incorporate dual process fluid circuits. This will provide redundancy in your system and will prevent your plant from being down.

The modular design of the KSE unit allows up to 480 Tons of cooling. Each of the units provides dual refrigeration circuits. With the 80, 100, 120 ton units they incorporate dual process fluid circuits. This will provide redundancy in your system and will prevent your plant from being down.

Designed for harsh outdoor environments KSE Series chillers operates within the widest ambient temperature ranges on the market, -20°F to 125°F. Flexible process fluid set point temperatures of 20°F to 80°F are ideal for industrial applications.

Designed for harsh outdoor environments KSE Series chillers operates within the widest ambient temperature ranges on the market, -20°F to 125°F. Flexible process fluid set point temperatures of 20°F to 80°F are ideal for industrial applications.

Reference:

Reference:

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

Hirate America is partnered with LS Mtron Injection Molding Machines (formerly known as LG Injection Molding Machines) who manufactures all electric injection molding machines in South Korea ranging from 20 to 950 US tons. We can provide a complete turn key solution including machines, molds, auxiliary and automation equipment. Contact us today to request more information and a proposal for your project.

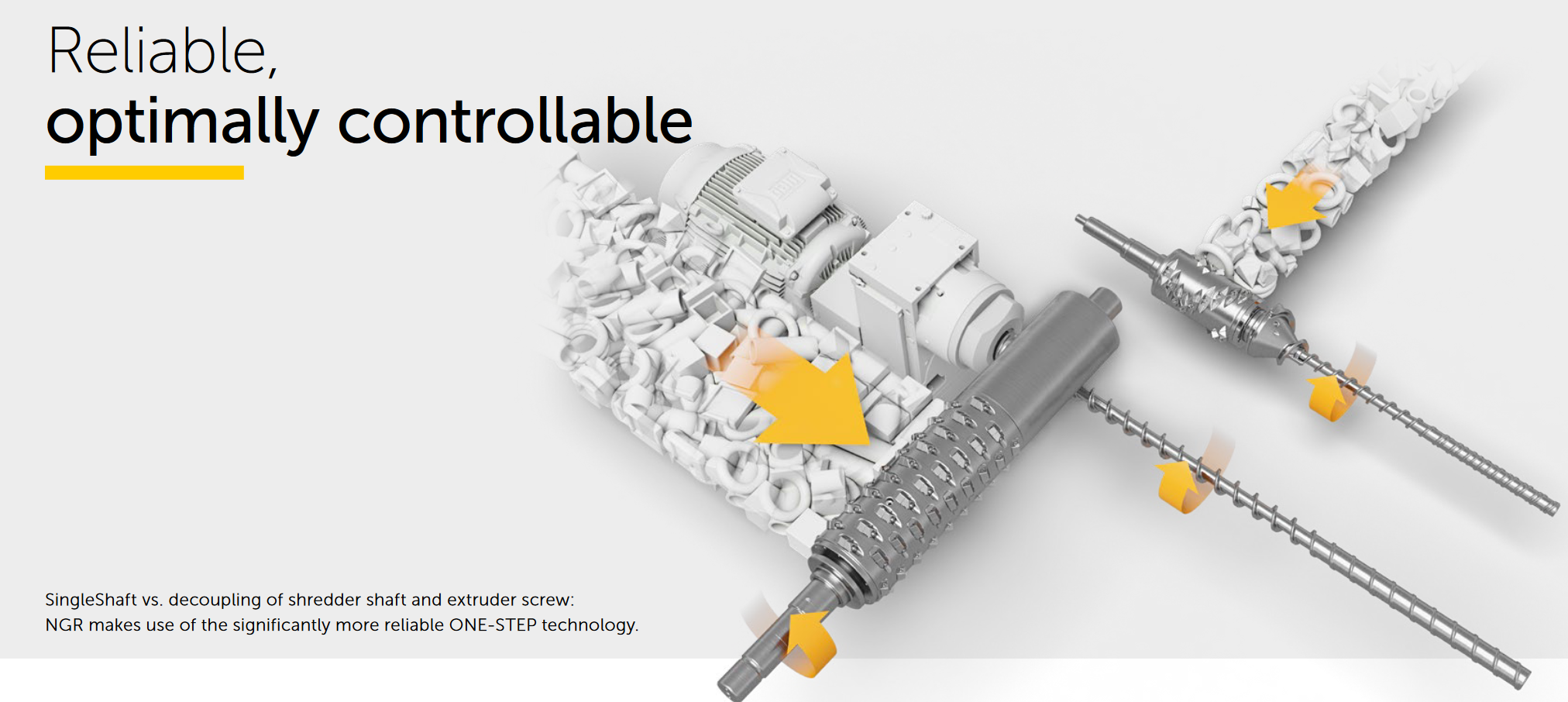

Both of these process components feature load-dependent and fully automatic control.

Both of these process components feature load-dependent and fully automatic control.