Process cooling is an essential piece of the puzzle needed for processing plastic.

Thermal Care offers a suite of powerful and efficient central chillers (air-cooled, water-cooled and remote condenser models) for the plastic industry. All of our units are reliable, easy to operate, packed with many standard features and built for dependable operation using an assortment of quality components. We are proud to produce one of the best process cooling equipment systems in the industry.

An industrial packaged, outdoor air cooled chiller provides cooling for single or multiple processes and is located outside of the manufacturing facility. The chiller incorporates the refrigeration circuit and PLC in one package and requires a pumping system.

Packaged, outdoor chillers use air-cooled condensers to ultimately reject the process heat. These condensers utilize surrounding ambient air to provide cooling for the system. This eliminates the need for any support systems such as a cooling tower system for water-cooled chillers or interconnecting refrigeration piping for remote air-cooled systems.

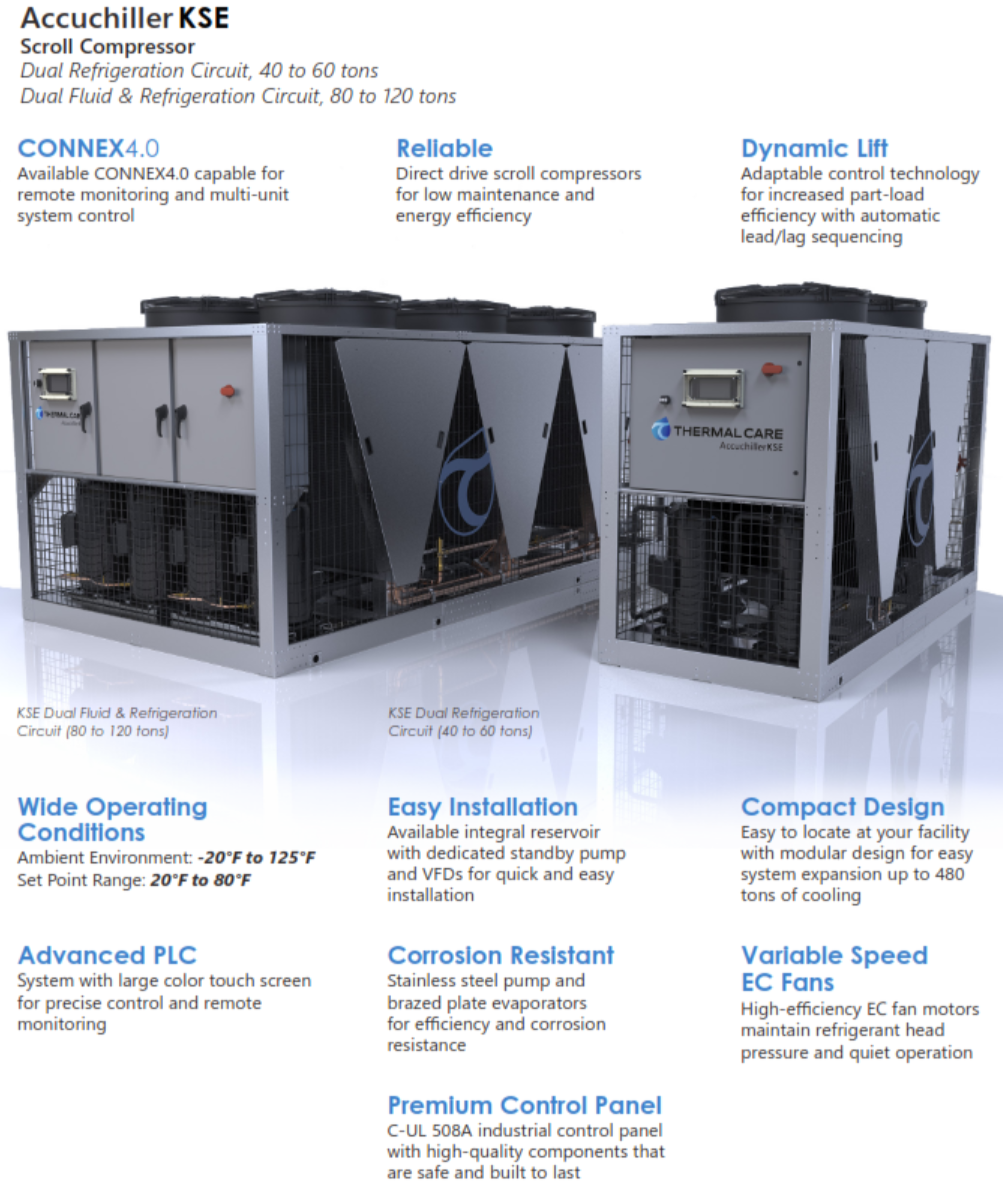

Why The Accuchiller KSE Outdoor Packaged Chiller Over Others?

-

Minimize Installation Time & Costs

Accuchiller KSE Series packaged outdoor chiller is an all-in-one package designed to minimize installation cost. The chiller system can ship on a standard flat bed truck, which comes on a skid for easy unloading and easy connection to your power (single point connection for electric hookup at control cabinet), water sources and most importantly minimizes freight costs. This will simplify rigging and placing the unit. To further makes things easier, the unit comes pre-charged with refrigerant.

Accuchiller KSE Series packaged outdoor chiller is an all-in-one package designed to minimize installation cost. The chiller system can ship on a standard flat bed truck, which comes on a skid for easy unloading and easy connection to your power (single point connection for electric hookup at control cabinet), water sources and most importantly minimizes freight costs. This will simplify rigging and placing the unit. To further makes things easier, the unit comes pre-charged with refrigerant.Add our variable integral reservoir with dedicated standby pump and VFDs for the ultimate turn-key quick and easy installation solution.

-

Ultra Compact Design Maximizes Usable Space

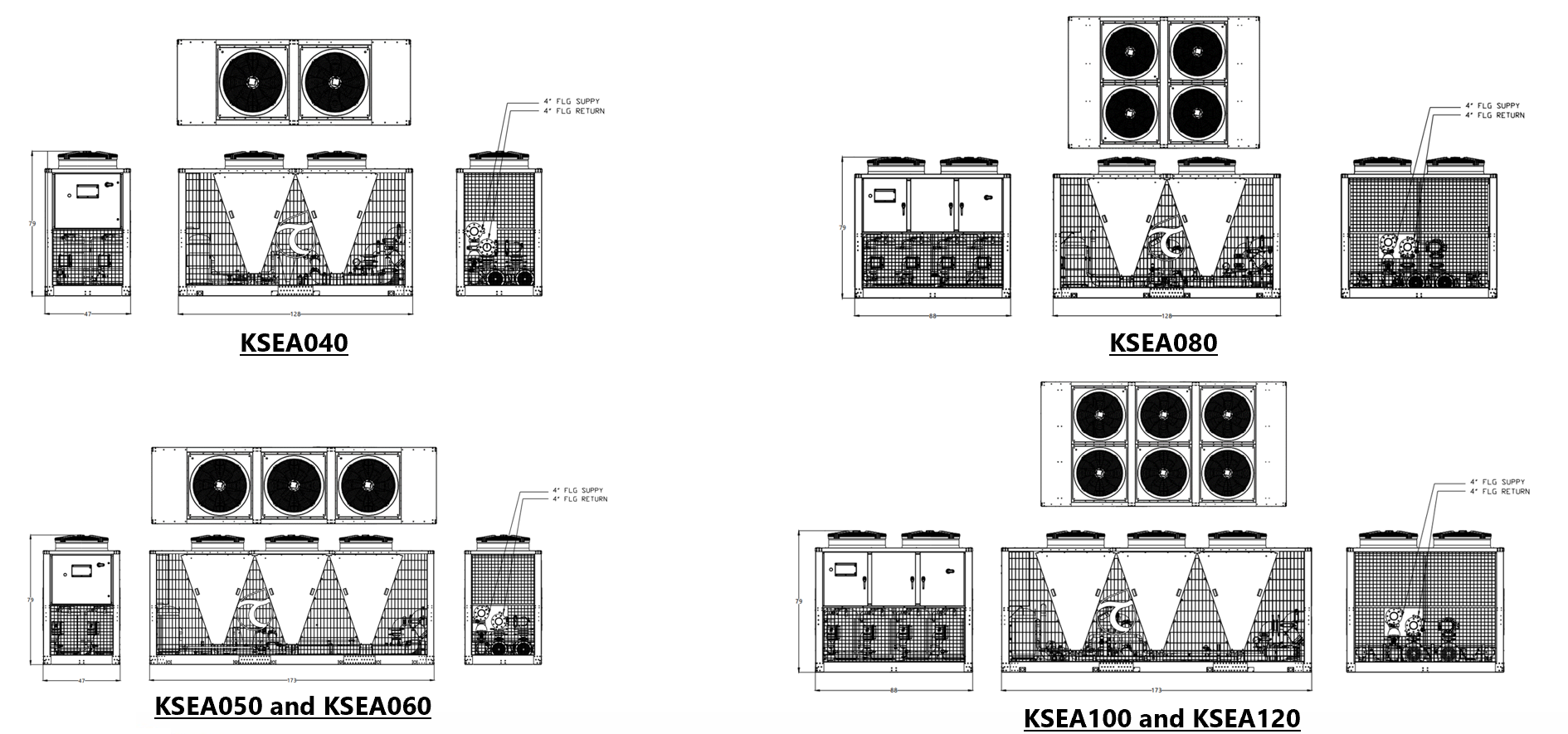

The modular design of the KSE unit allows up to 480 Tons of cooling. Each of the units provides dual refrigeration circuits. With the 80, 100, 120 ton units they incorporate dual process fluid circuits. This will provide redundancy in your system and will prevent your plant from being down. The PLC control integrates up to 12 circuits across multiple chillers and automatic compressor lead/lag sequencing comes standard to extend the life of the unit as Thermal Care products are known to be one of the most reliable systems in the industry.

The modular design of the KSE unit allows up to 480 Tons of cooling. Each of the units provides dual refrigeration circuits. With the 80, 100, 120 ton units they incorporate dual process fluid circuits. This will provide redundancy in your system and will prevent your plant from being down. The PLC control integrates up to 12 circuits across multiple chillers and automatic compressor lead/lag sequencing comes standard to extend the life of the unit as Thermal Care products are known to be one of the most reliable systems in the industry.

-

Industry Best Wide Operating Conditions

Designed for harsh outdoor environments KSE Series chillers operates within the widest ambient temperature ranges on the market, -20°F to 125°F. Flexible process fluid set point temperatures of 20°F to 80°F are ideal for industrial applications.

Designed for harsh outdoor environments KSE Series chillers operates within the widest ambient temperature ranges on the market, -20°F to 125°F. Flexible process fluid set point temperatures of 20°F to 80°F are ideal for industrial applications.

BONUS: You Want Smart Technology That Saves Time

The Accuchiller KSE outdoor packaged chiller comes standard with Thermal Care’s latest 7″ color touch screen with advanced PLC controls that provides real time diagnostics. This enables you to troubleshoot and solve issues quickly, which saves valuable time and headaches. This feature is a maintenance crew’s dream come true. Optional CONNEX4.0 technology allows remote monitoring and multi-unit system control with secure access and control to all your Thermal Care connected equipment so you can have confidence your process is running without issues.

Featured Specifications

Hirate America partners with Thermal Care, a leader in manufacturing of industrial grade water chillers, process cooling equipment and systems for applications worldwide. As an ISO 9001 certified manufacturer, Thermal Care provides heat transfer equipment for over 50 industries and specializes in offering both standard and custom designed industrial process cooling solutions.

If you have any questions regarding portable chillers, please contact any of the Hirate America team members to provide a process cooling solution tailored to your requirements.