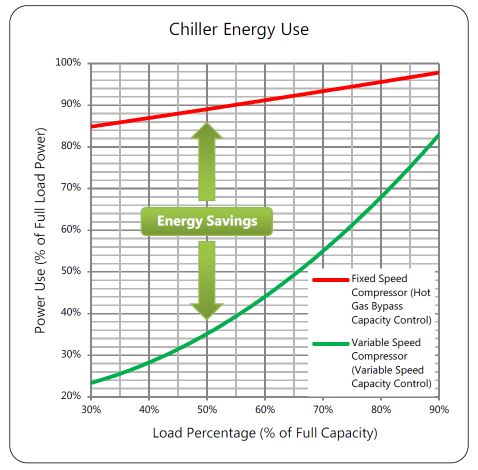

Standard fixed speed compressors on chillers use a hot gas bypass valve that bypasses hot discharge refrigerant gas back into the compressor to simulate 100% load. This keeps the compressor running at full speed at all times regardless of the actual load. As an example, this means that if you have a 10 TON chiller and have 10 machines that each require 1 TON of chilling, or 2 machines that require 5 TONs each, you will be running your chiller at 100% capacity, regardless of whether you have 8 of your 10 machines running (80% load) or 1 of your 2 machines running (50%) load. With this example, the chiller will be costing you a fixed amount on your energy bill regardless of how many of your machines are running.

Thermal Care introduced the first portable chillers with a variable speed compressor on their 10 TON and 20 TON portable chillers. It allows the compressor to reduce the actual output from 100% down to 30% by reducing the speed of the compressor while utilizing hot gas bypass to bring the load from 30% all the way down to 0% without shutting off the compressor. As shown in the graph below, the energy savings often result in less than a 1 year return on investment.

Key Features:

- Touch Screen PLC with full diagnostics

- Totally enclosed, air-over (TEAO) low-noise, energy-efficient fan(s)

- Removable tools-free access door

- Power 3-phase error alarm

- Warranty – lifetime controller replacement ($175 after 5 years)

How do you calculator your cooling your process requirement?

Click the link below for a simple calculator to get a good estimate on your cooling tonnage.

https://www.thermalcare.com/plastics-chillers-calculator/

Want to estimate your annual energy savings (above 50 TONs)?

https://www.thermalcare.com/tc-central-calculator/

Hirate America partners with Thermal Care, one of the best process cooling equipment and systems for removing heat from industrial applications.

If you have a project that you would like to discuss, feel free to contact us below to schedule a free consultation.