This will be a 3 part series (Vacuum, Gripper and Lifting technology) from FIPA, End of Arm Tools (aka EOAT).

If you have a robot to pick out parts from the mold it’s essential to have a properly designed EOAT which is the robot’s customized hand to extract your parts and runners.

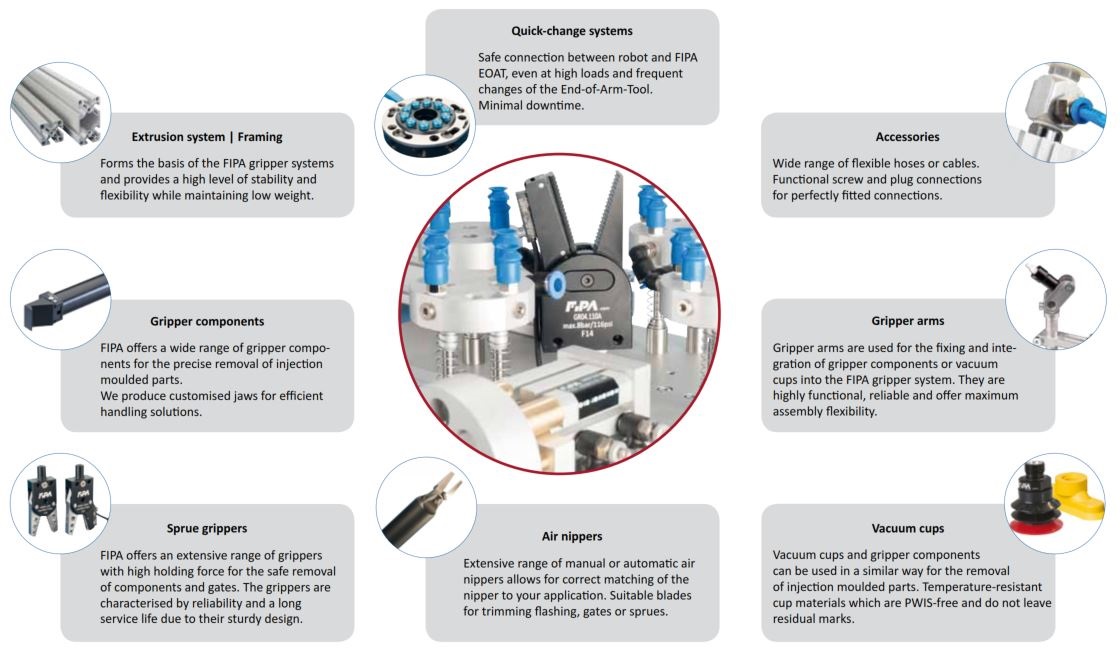

FIPA specializes in EOAT (suction cups, grippers, cutting shears, lifting) and can customize the design to your specifications.

![]()

Part 2: Gripper Technology

Grippers are like fingers for your robot. There are some many different types of options available for your needs, all sizes as well as direct sensing technology to detect when the part is secure.

Miniature grippers are perfect for very tight spaces with clamping diameter of 10mm.

Parallel and angular grippers accurately positioned gripping, lifting up and depositing of components.

2 finger for pick and place, 3 finger for precise handling like inserts, angular for undercut or clamping components.

Gripper fingers with 35° and 95° angle stroke and option for gentle gripping with HNBR elastomer pads.

ID grippers that expand pneumatically clamps workpieces at its inner surface and holding force controlled by feed pressure. Diameters range from 8mm ~ 81mm.

Air nippers (air scissors) are perfect for separating and cutting of plastic sprues or even metal wires.

Hirate America partners with FIPA, a German based company that’s leading the industry in end of arm tooling design and components.

As you can see there are many options for your application. Whether you want to purchase individual components or have a full turn key gripper system designed for your automation solution, FIPA & Hirate America has you covered with the following:

- Quick change systems

- grippers

- parallel and angular grippers

- ID grippers and gripping fingers

- magnetic grippers

- needle grippers

- air nippers (scissors)

If you have any questions or need help with a custom designed end of arm tool, please contact any of the Hirate America team members to provide an automation solution tailored to your requirements.