Everything You Need to Know About Vision Mold Protection Systems for your Injection Molding Machine

What is a vision injection mold protection system?

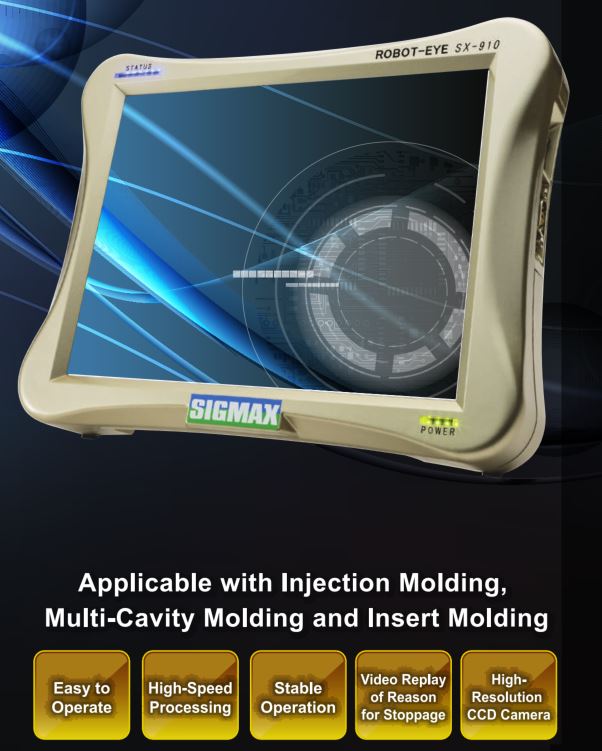

The Sigmax vision injection mold protection system is made specifically for injection molders in mind and integrates directly into the control systems for the injection molding machine so communication between systems is instantaneous for high-speed processing.

The ultimate goal for the Sigmax vision mold protection is to prevent mold damage, which leads to costly repairs and weeks or even months of downtime. This is not good for any business especially if you’re running lights out. The unit has many other useful functionalities for injection molding.

What type of injection molding machine can this be used on?

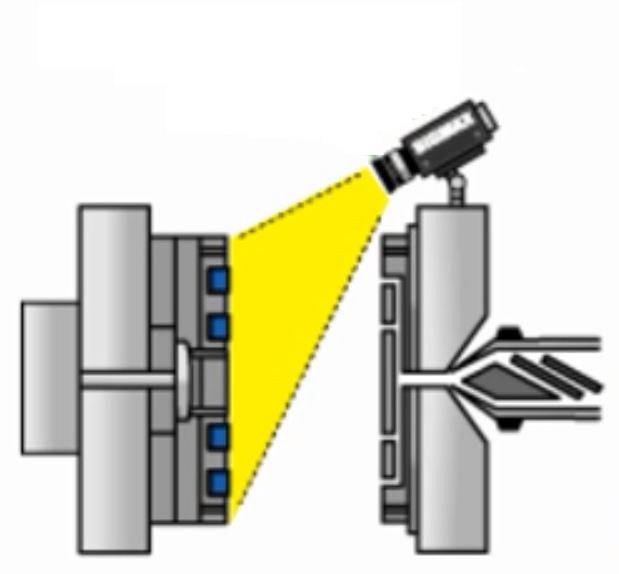

Vertical and horizontal molding machines, high-cavity molds, low-pressure foam molding, metal injection molding (MIM), die-casting, micro-molding, and other forming machines, regardless of the materials being molded or formed.

Is there a mold size limit?

No, there is no size limit as we have several options for camera lens sizes that can be scaled accordingly.

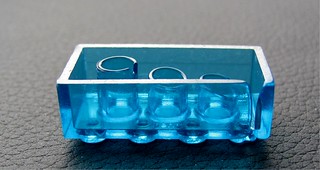

How many molded parts can be monitored?

We have monitored up to 128 cavities, dependent on the mold design.

Is it possible to monitor injection short shots?

Yes, it possible to detect short shots of 0.001 in size (0.25mm).

Is high cycle molding possible with the Sigmax Vision Mold Protection system?

Yes, communication is instantaneous as this unit has the capability to monitor 1 second cycles.

What if my parts are transparent?

Yes, it is possible to monitor transparent parts as the software allows for adjustment in sensitivity and shadows.

How can the Sigmax Vision Mold Protection System reduce molding cycle time?

The unit ties directly into the I/O signal system controls of the injection molding machine there is no lag. Since you eliminate the need for unnecessary ejections, production over a period of time will be much more efficient.

How easy is the installation?

The camera is magnetic so it can be attached above or below the mold. Once the required input and output signals are established connection very simple.

Can I use the Sigmax Vision Mold Protection System on multiple injection molding machines?

Yes, it is possible to use one system on multiple molding machines, but it is important to assure exact location of camera from the saved in the recipes. The unit has the ability to save multiple recipe setups with different areas you want to monitor or different jobs/molds and easily re-accessed later, which makes this system very versatile.

How reliable is the Sigmax Vision Mold Protection system and what is the typical service life cycle?

The unit can run problem-free for decades because there are no moving parts. The user interface is a proprietary standalone system that does NOT rely on any third party software like Microsoft Windows OS, you will not have to worry about automatic updates that may disrupt functionality and worse yet deal with viruses that may corrupt your hardware.

What is the typical ROI on the Sigmax Vision Mold Protection System?

Repairs for ejector pins and slide cores can cost several thousand dollars, but if you have substantial enough damage to the mold the entire mold may need to be replaced. Not only do you have to deal with cost of replacing the mold, but what would hurt the most is the downtime in production. In this instance, the payback would be tenfold.