ECON has been THE underwater pelletizing specialist for over 20 years so “PELLETIZING IS IN OUR DNA.” Request a quote.

ECON Advantages

Why ECON:

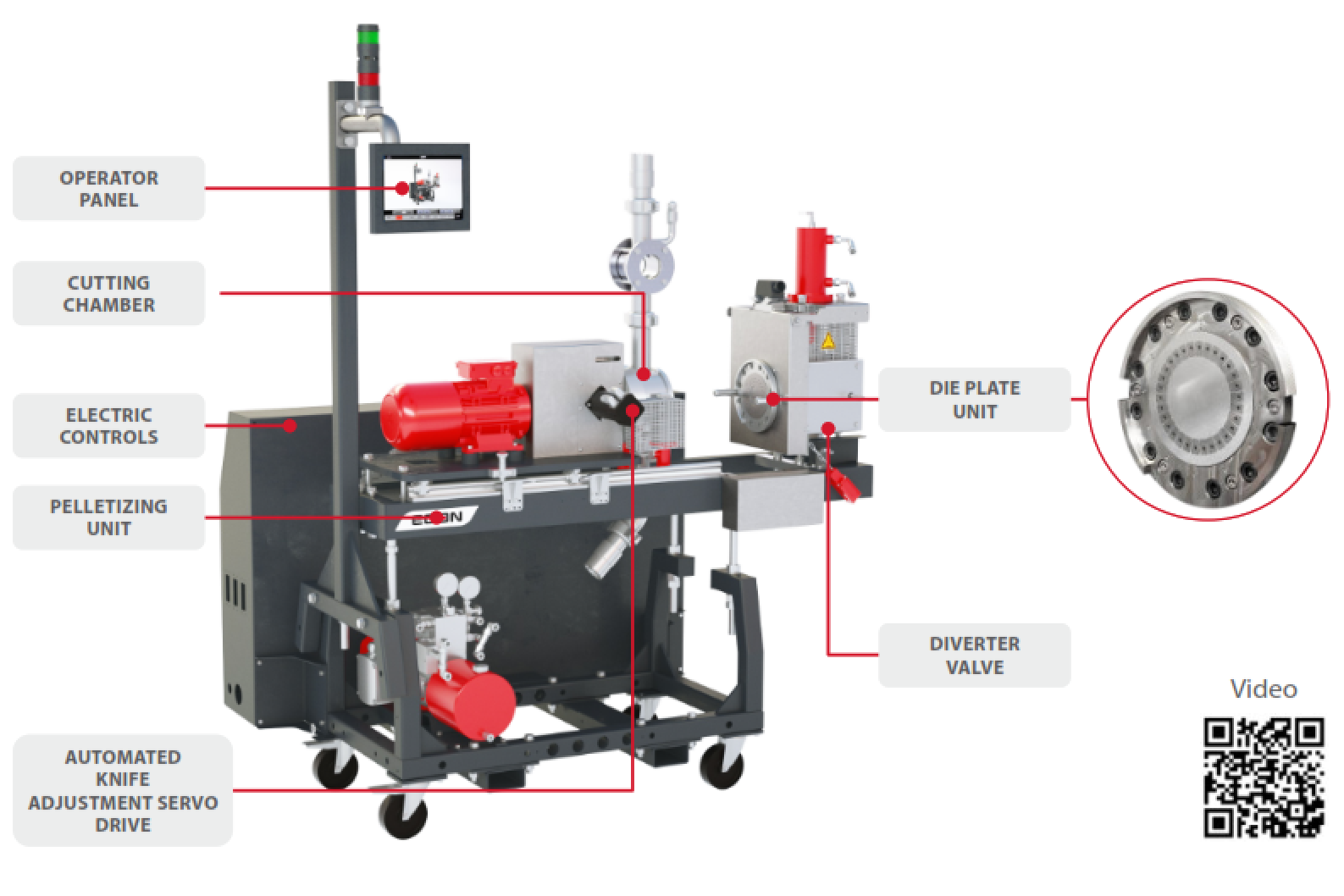

- Push-button start – automatic, fast and safe

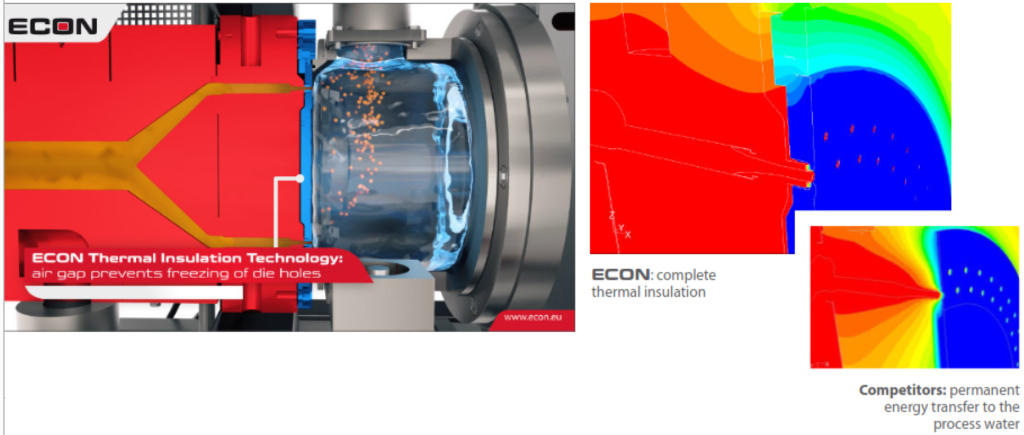

- The “freezing” of die holes can be prevented due to the thermal insulation technology

- Servo driven cutter hub control offers accuracy and machine safety

- Consistent pellet quality

- Integrated diverter valve controls resin in bypass

- No water bypass required, no water on floor

- Streamlined die provides no pressure build up, and minimum melt loss

- Compact unit, minimal space requirements, simple handling

- Pelletizer moves and functions as a complete unit

- Minimal energy consumption

- Low labor and maintenance costs

Polymer Diverter Valve:

- All thermoplastic materials can be processed in all sizes (micro, mini, standard)

- Highest process stability

- High-quality pellets

- Tailor-made solutions for your individual requirements

- Compact unit, minimal space requirements, simple handling

- Only 1 operator is needed

- Diverter valve for easy handling (included in the standard scope of supply)

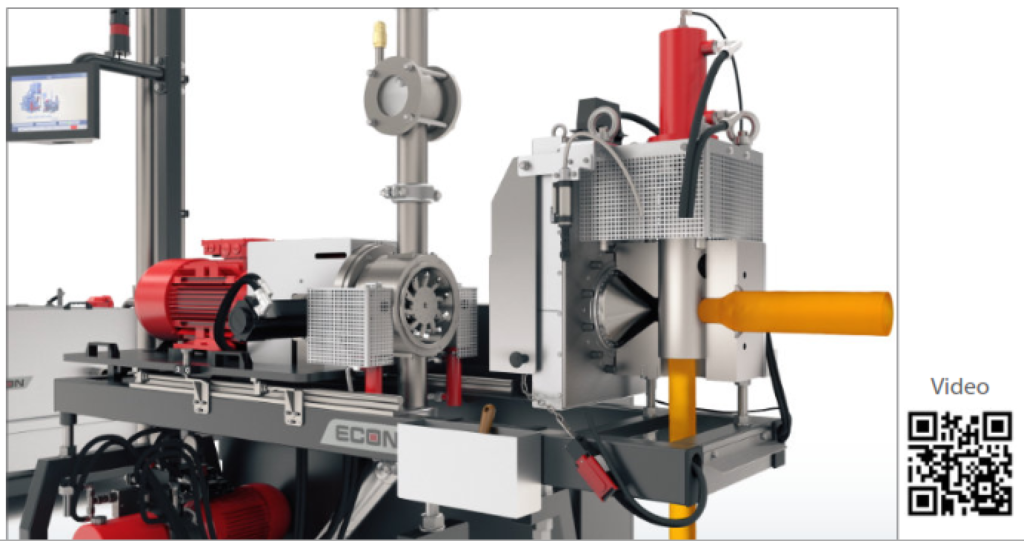

Die Plate Unit:

- No “freezing” of die holes – provides constant high pellet quality

- Thermally insulated die plate – provides constant temperature through the carrier body & no overheating of the melt

- Reduced energy demand

- Die plate features easy handling, easy cleaning and quick change system

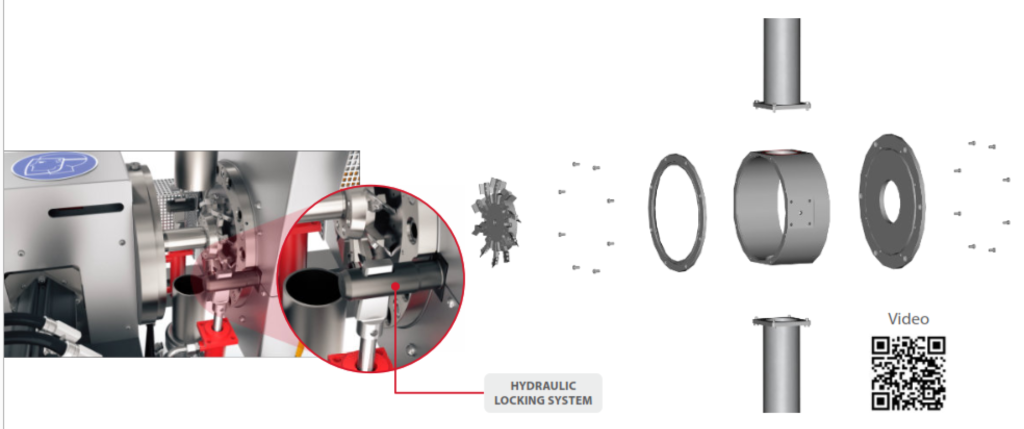

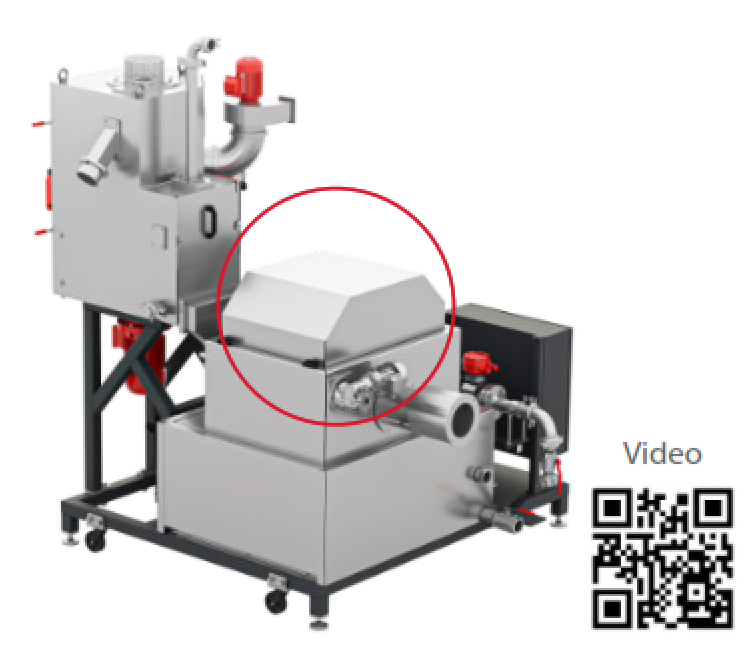

Cutting Chamber:

- Hydraulic locking system

- Easy to dismantle

- Easy to clean

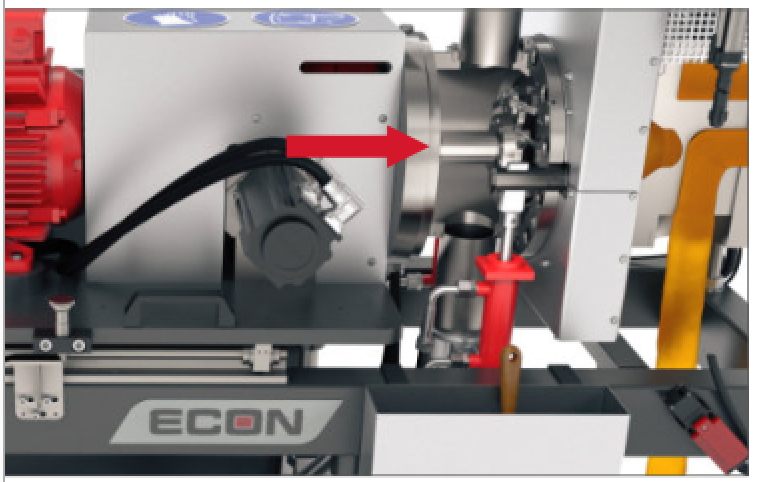

Automatic Knife Adjustment Servo Drive:

- The servo motor controls the position and force of the knife carrier against the die plate. The hydraulic locking system ensures proper adjustment and safe operation.

- Accurate knife adjustments by servo drive

- Automatic start sequence – fast and safe

- Online process monitoring of key process parameters for reproducible production processes

- Knives can be regrinded during production process

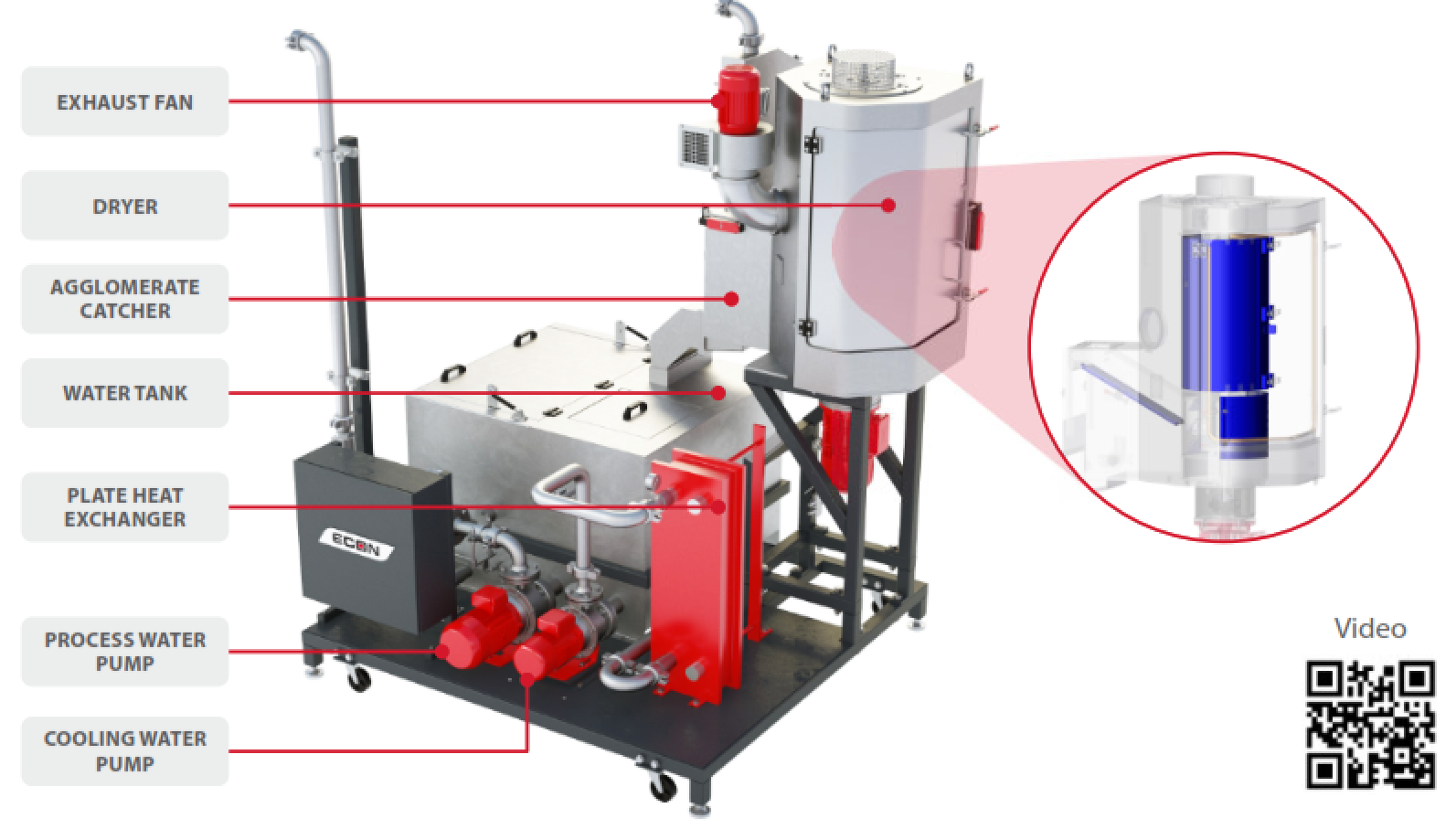

Water Treatment And Centrifugal Dryer:

Econ Water Treatment, EWT

- Pre-dewatering unit for best drying performance

- Clean process water will be recirculated – minimal water consumption

- Process water circle are separated to increase the lifetime of the heat exchanger

- Permanent control of the process water temperature

Econ Centrifugal Dryer, ECD

- Easy access for cleaning and inspection

- Highly wear resistant option for aggressive application

- Screen and rotor suitable for micro pellets

- rotor plates bolted for easy changing

EWT Optional Equipment:

Econ Water Filtration Advanced (EWFA)

- Continuous filtration of the process water using a band filter

Econ Water Filtration Professional (EWFP)

- Self-cleaning

- maintenance free

- full automatic operation no manpower required

- low operation costs and no additional process water

- high grade of filtration (less than 120 microns)

What They’re Saying

“Their experience and knowledge, speed of delivery and quality of service we encountered throughout our project was simply world class. There is incredible peace of mind knowing that you’re in the hands of professionals. Their work is of such outstanding quality, they are clearly experts in their field.”

Larry

Contact

We’re always interested in new projects, big or small. Please don’t hesitate to get in touch with us regarding your project.

If you want to contact us about any issue please call 909.979.7813 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.